We are a family-owned company with polish

assets which has been on the market since 1990

We specialize in production

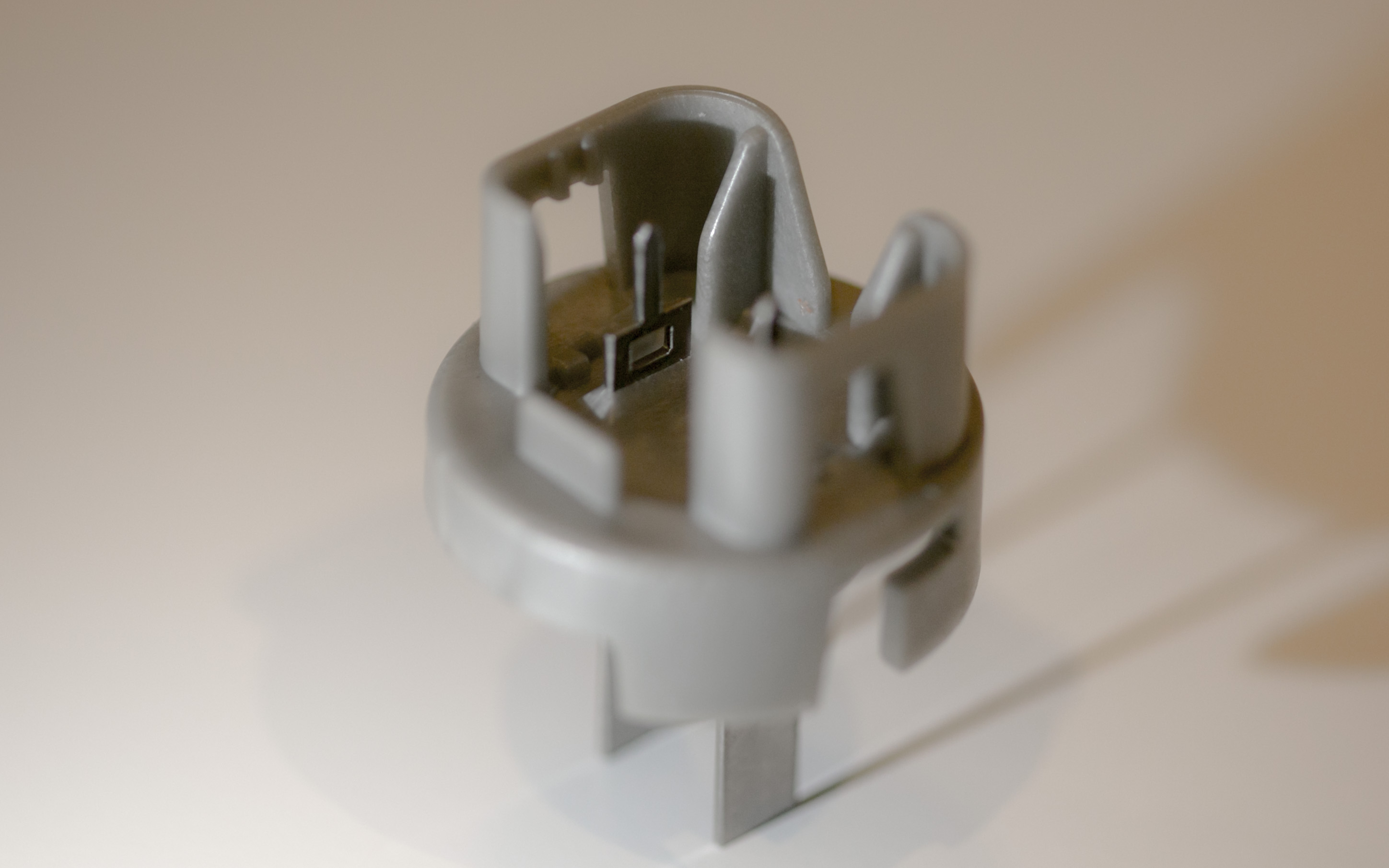

of technical plastic components

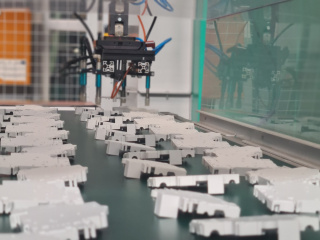

We are a family-owned company with polish assets which has been on the market since 1990. We have started in a garage on one entrusted injection machine. Today we have an innovative production facility with the area above 3800 sq m. We specialize in production of technical plastic components.

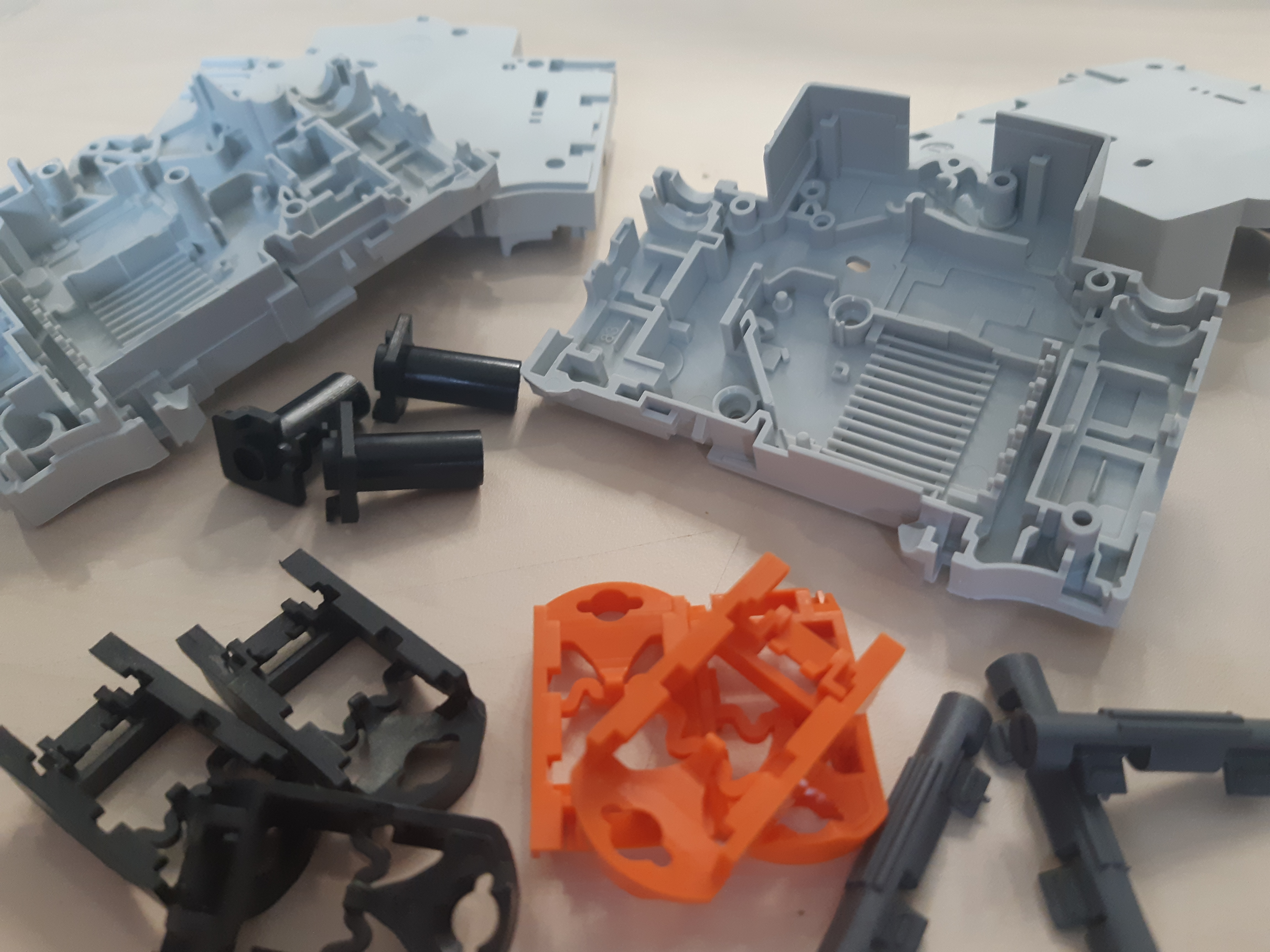

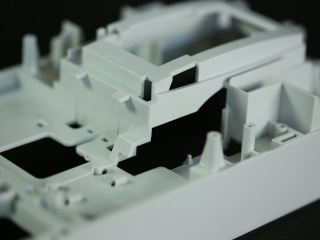

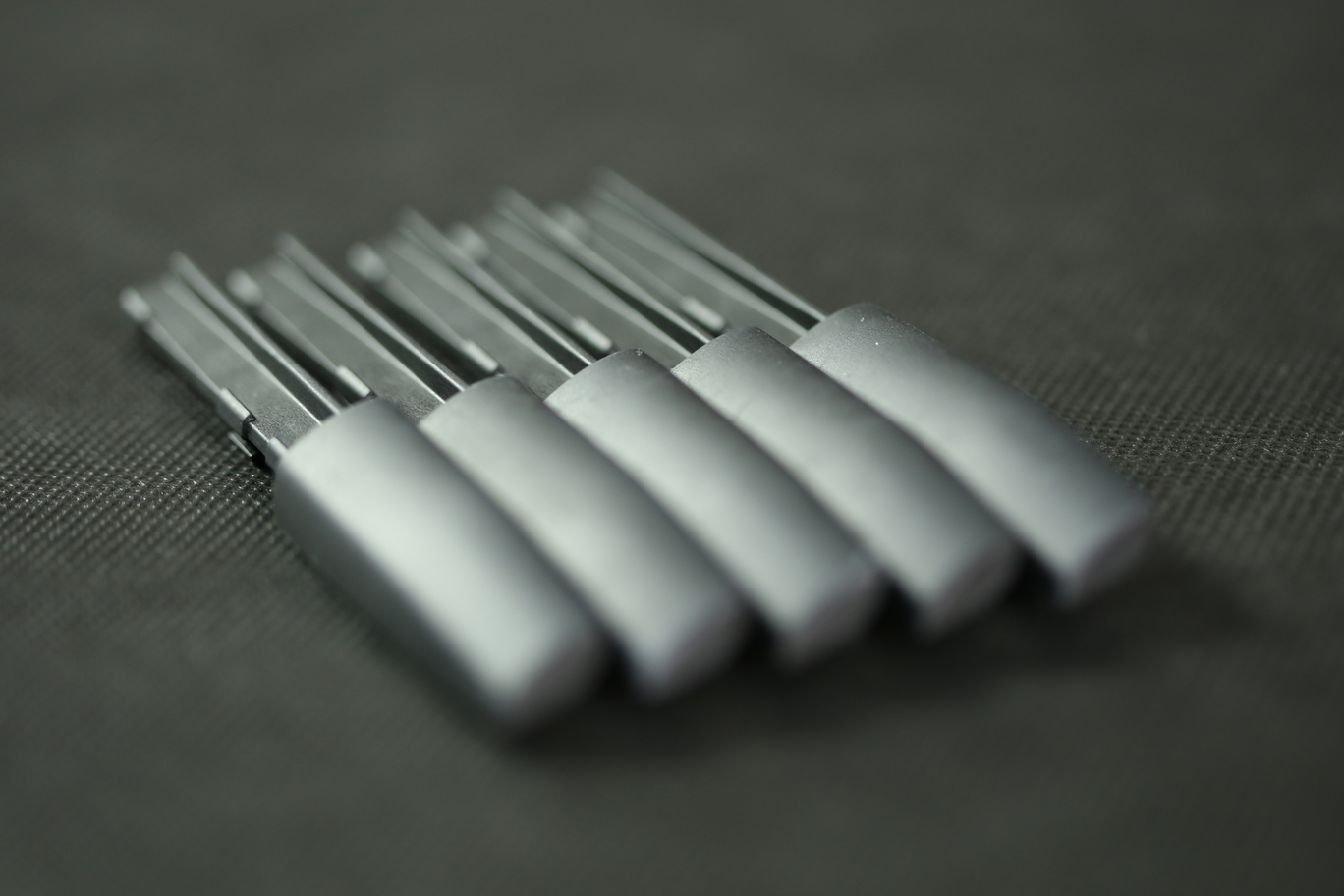

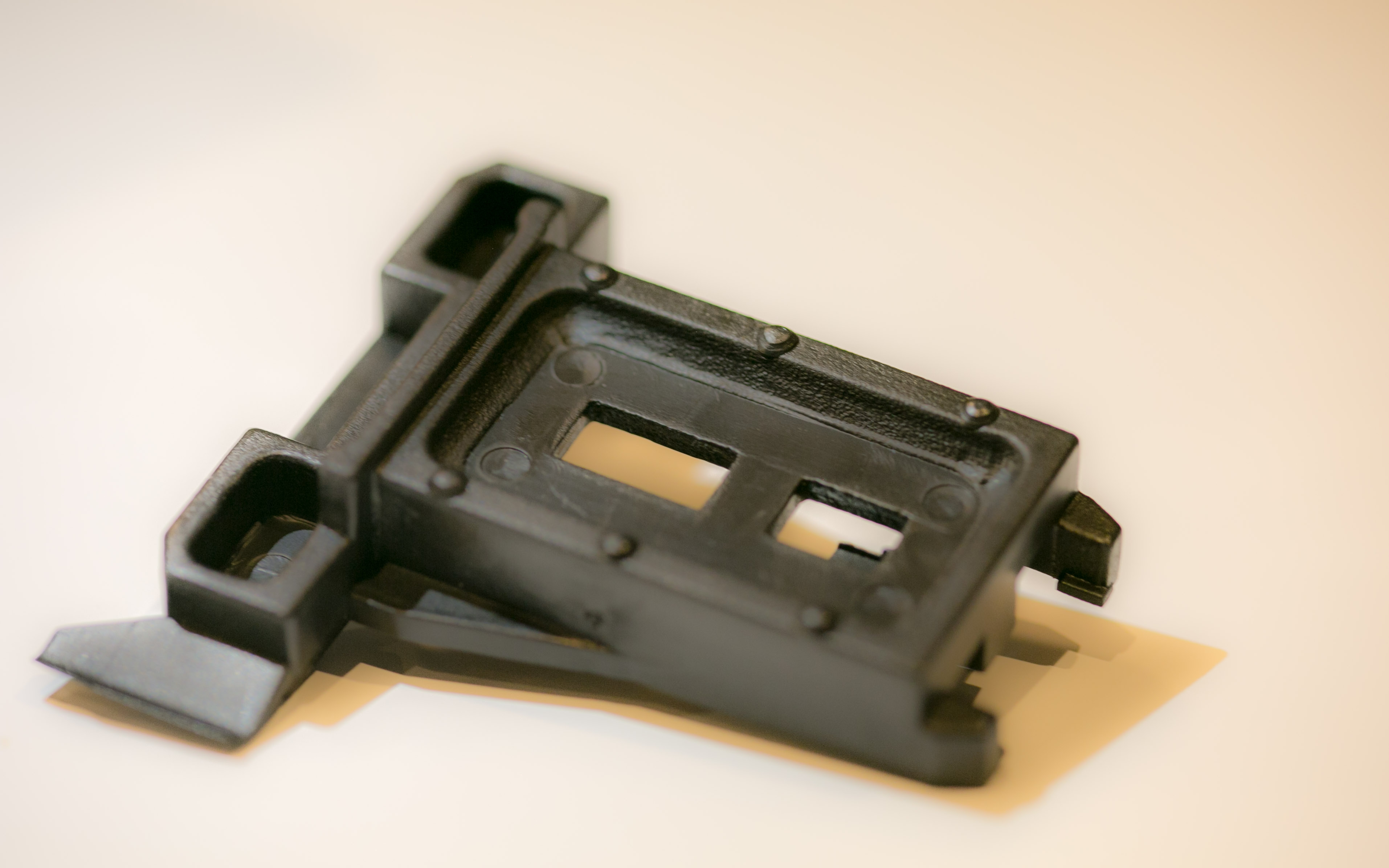

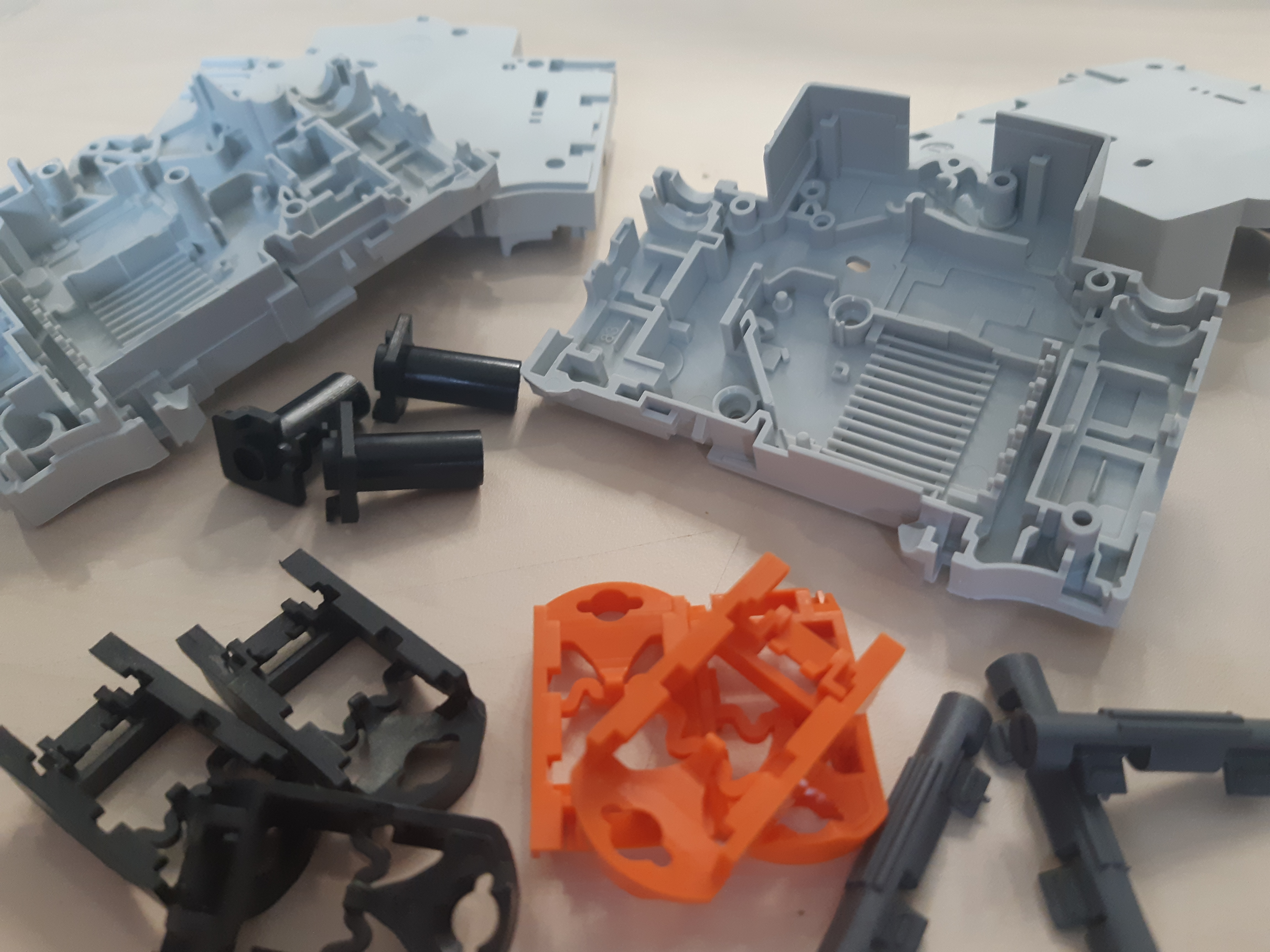

In our production floor there are 58 innovative injection presses with clamping force from 25 up to 800 tons including electrical, vertical, hybrid, 2K as well as gas injection machines. We also have our own independent tool-shop, where we design and make injection moulds and provide maintenance and service of our tools.

The main recipients of our products are world-known customers from diverse industrial sectors - electro-technical, automotive, home appliance, interior decoration, hydronic engineering and building.

Our success is due to a great number of wonderful people who have worked with us and contributed to the development of our company. Actually we have nearly 195 employees hired by Improdex and about 12 temporary workers who deal with parts control and assembly.

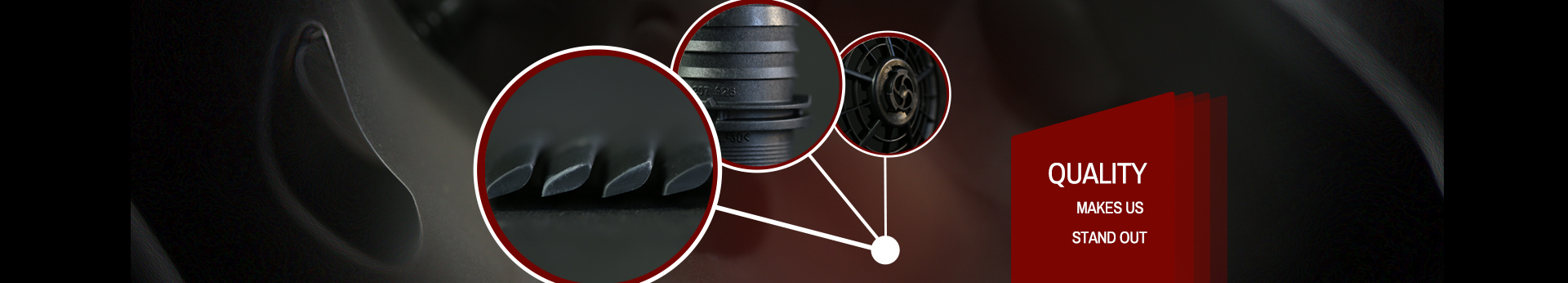

A high quality production is our priority, therefore we have implemented and use IATF and ISO 9001 rules. As a result, our customers have awarded several times our company for setting the standards of exceptional quality, dedicated service and commitment to excellence.

Our policy is customer satisfaction and continuous development of our company.

We invite you to cooperation

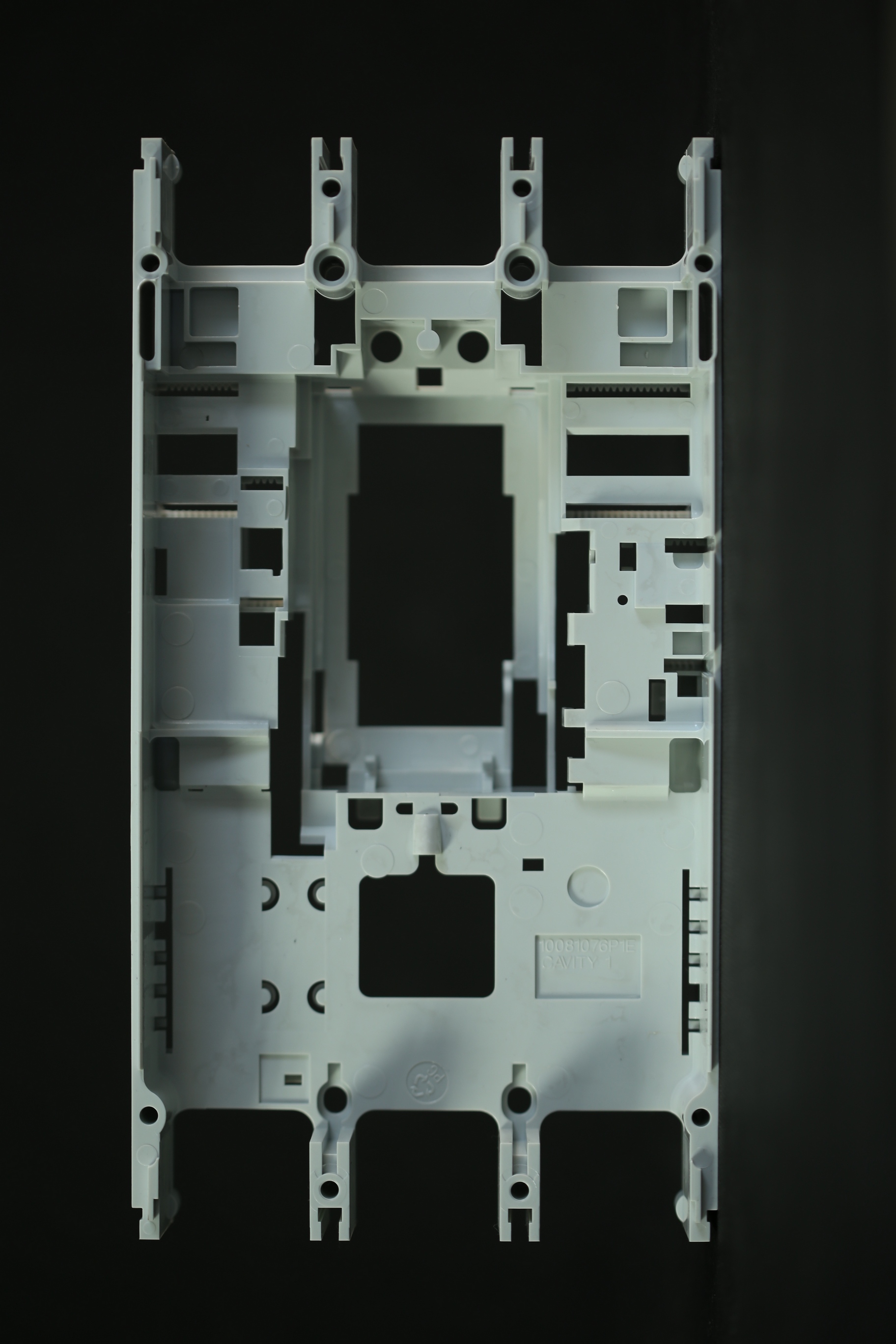

OUR PRODUCTION

Demanding technical components for industrial sectors.

-

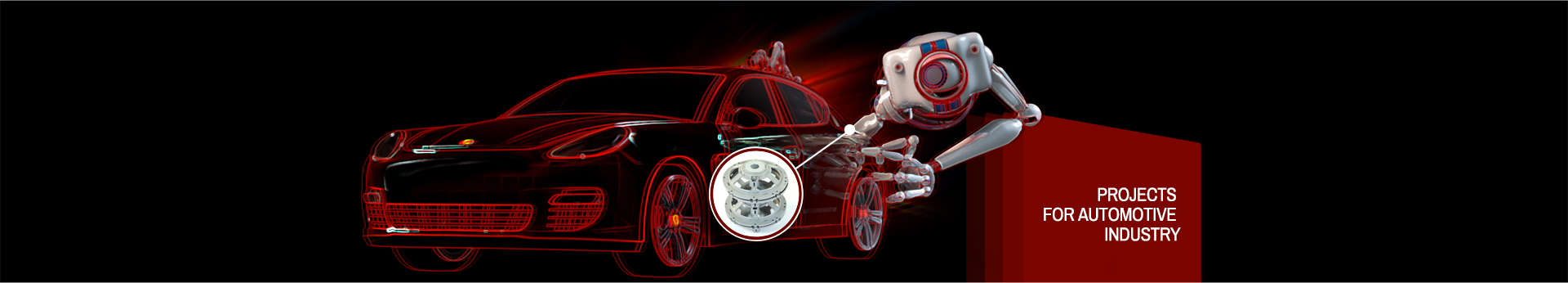

Automotive

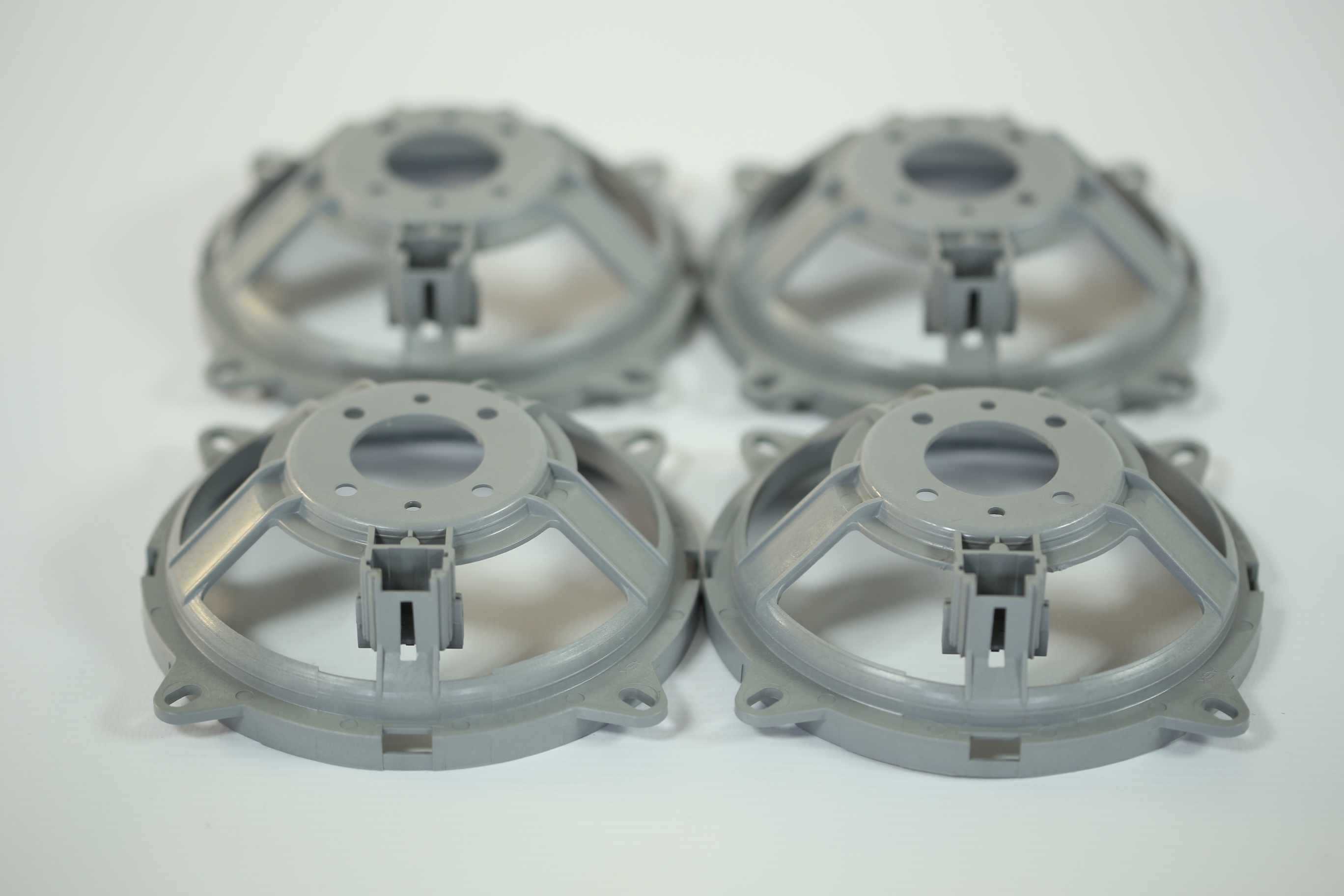

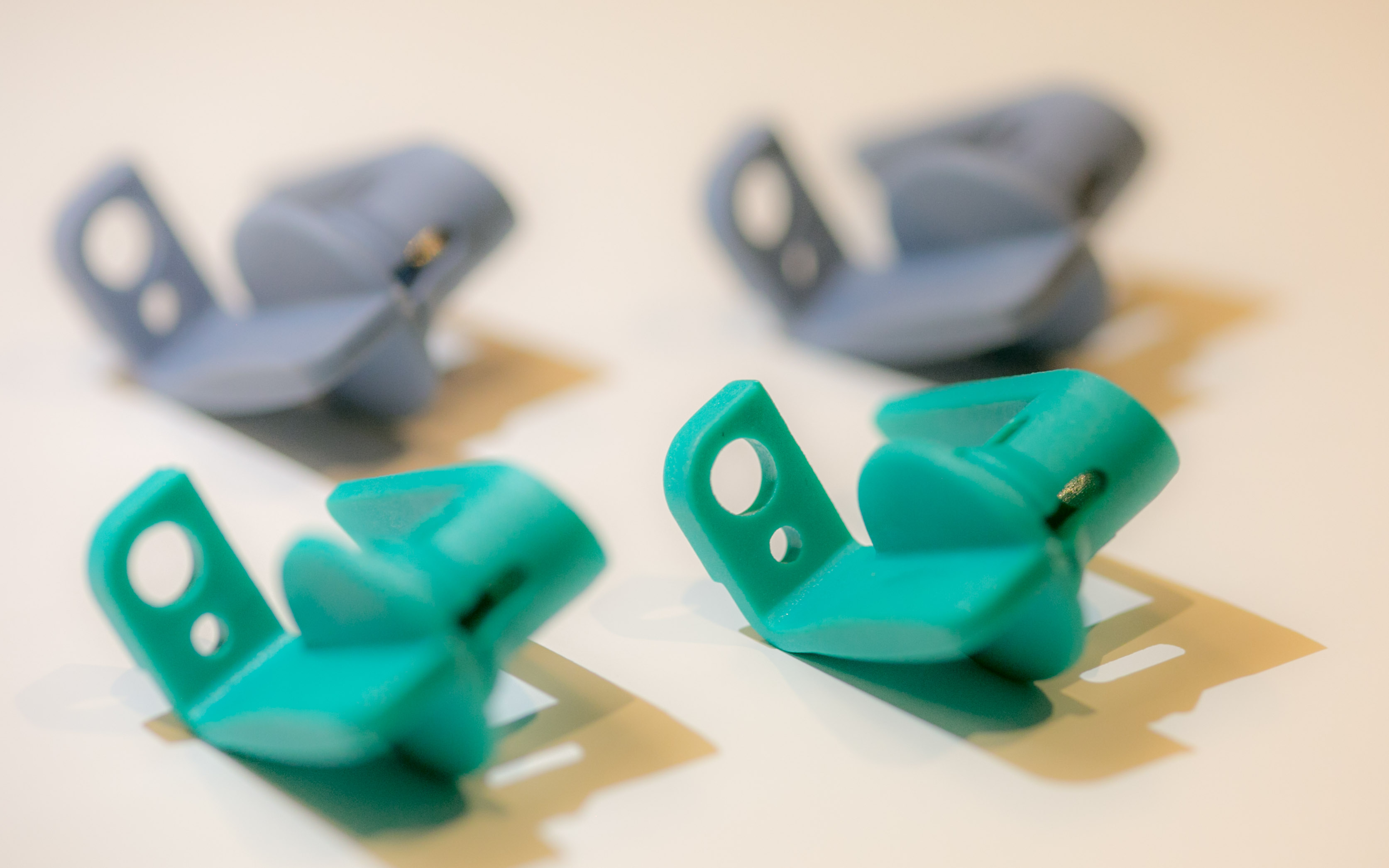

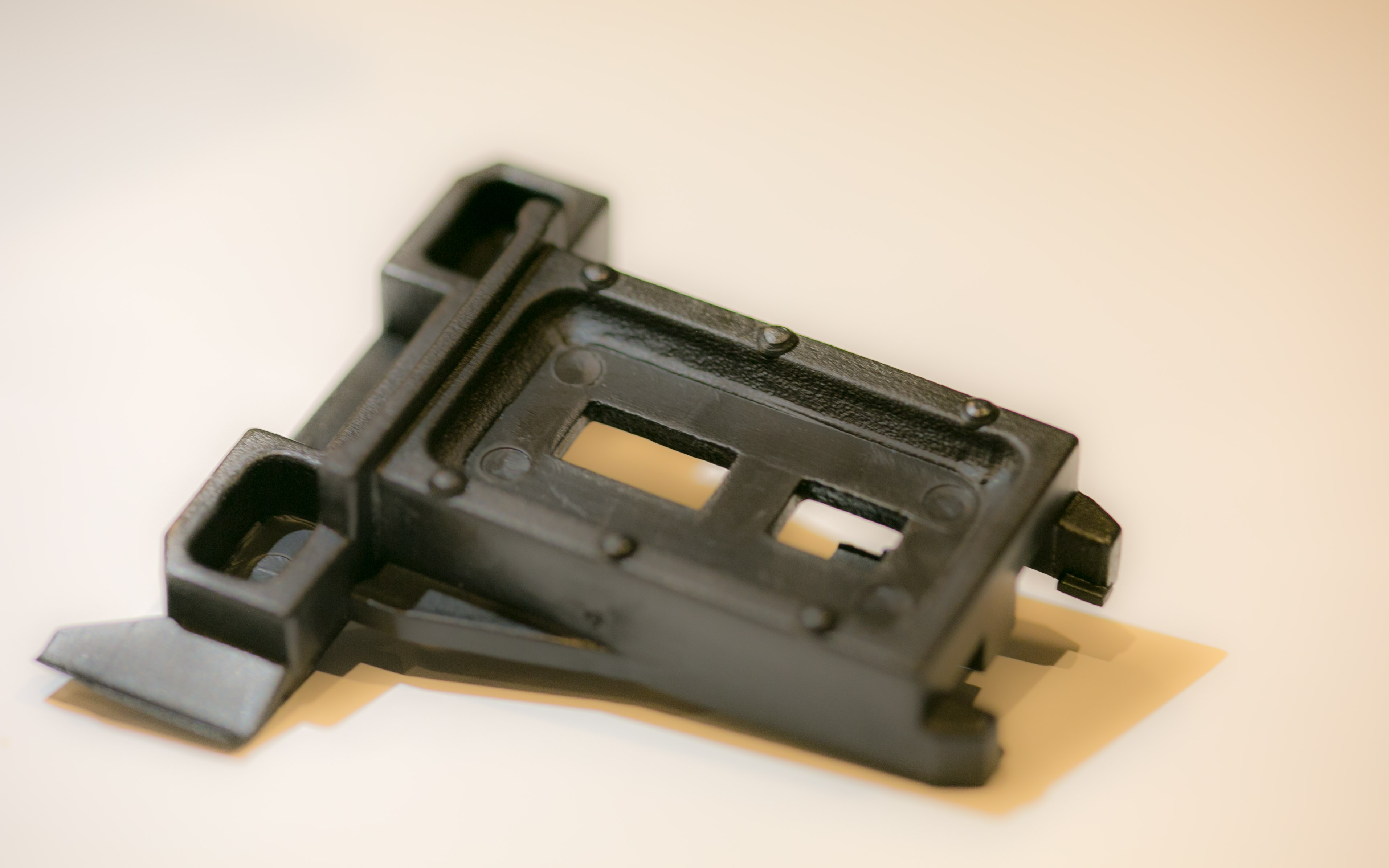

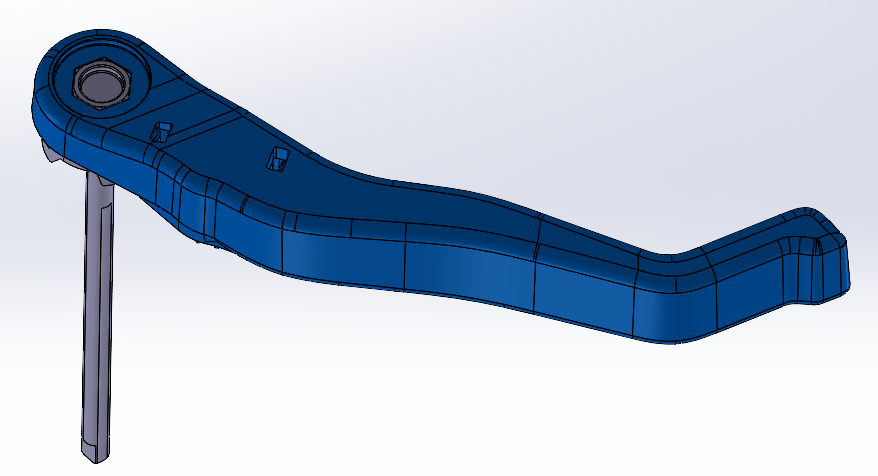

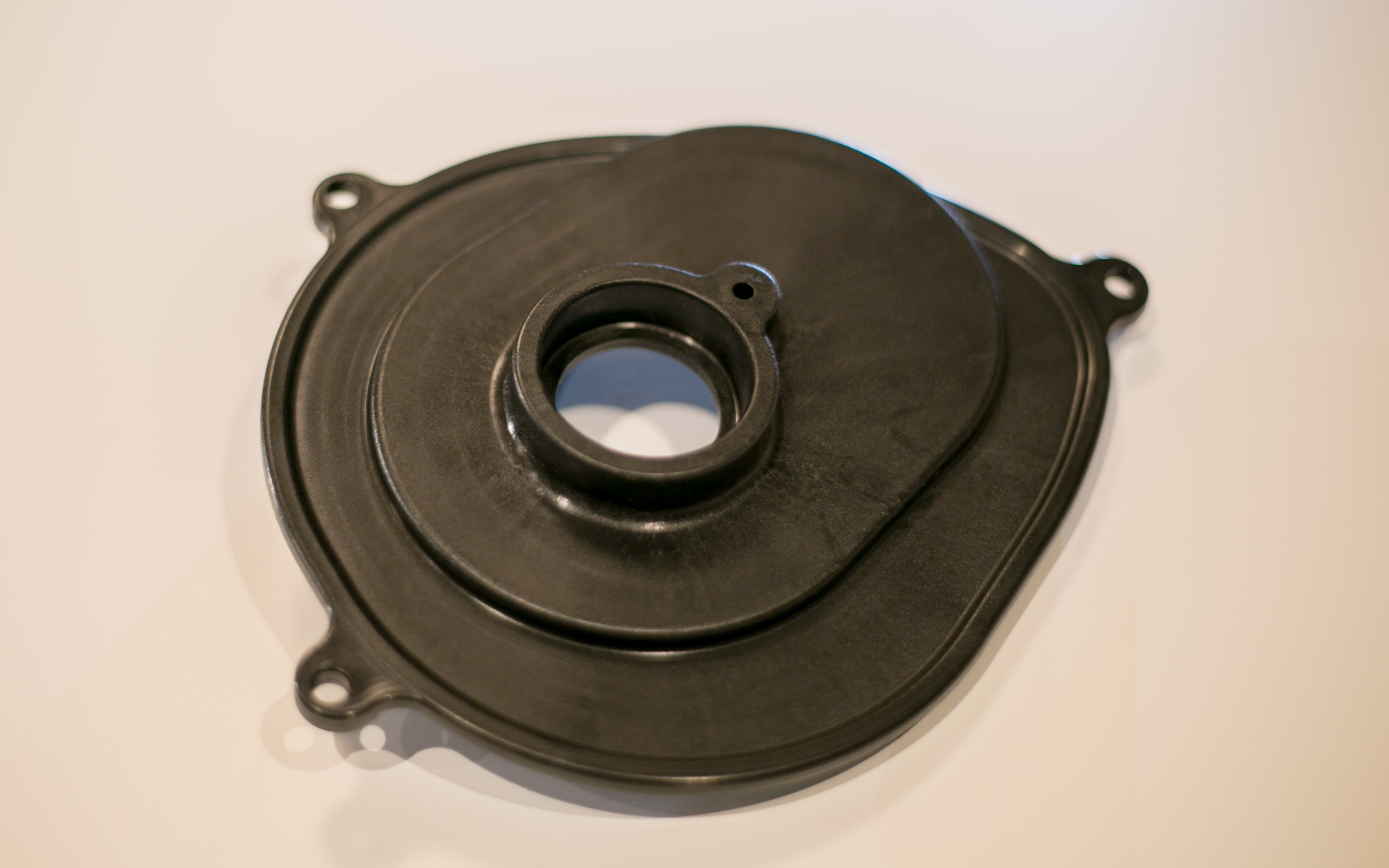

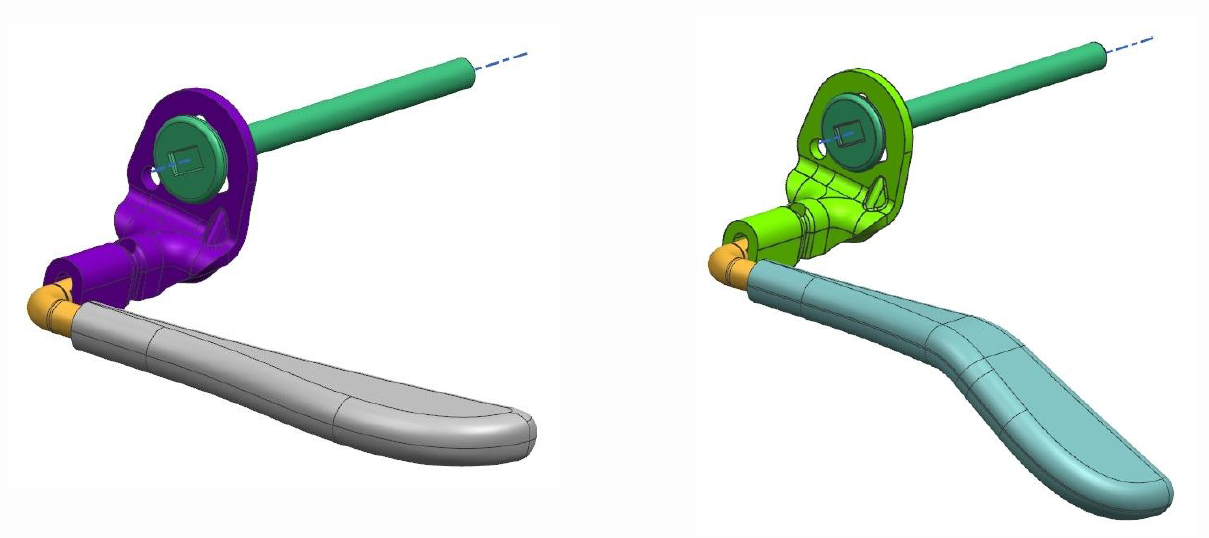

In 1998 we have started production for automotive sector making some simple plastic parts for Delphi Automotive. Currently we realize complex projects for several TIER 1 customers, producing more than 300 demanding technical plastic components. There are mainly parts for suspension systems, steering columns, cooling and ventilation systems, transfer of liquids and also audio-sounds systems. In our portfolio there are also interior car body plastic parts including demanding visual components.

-

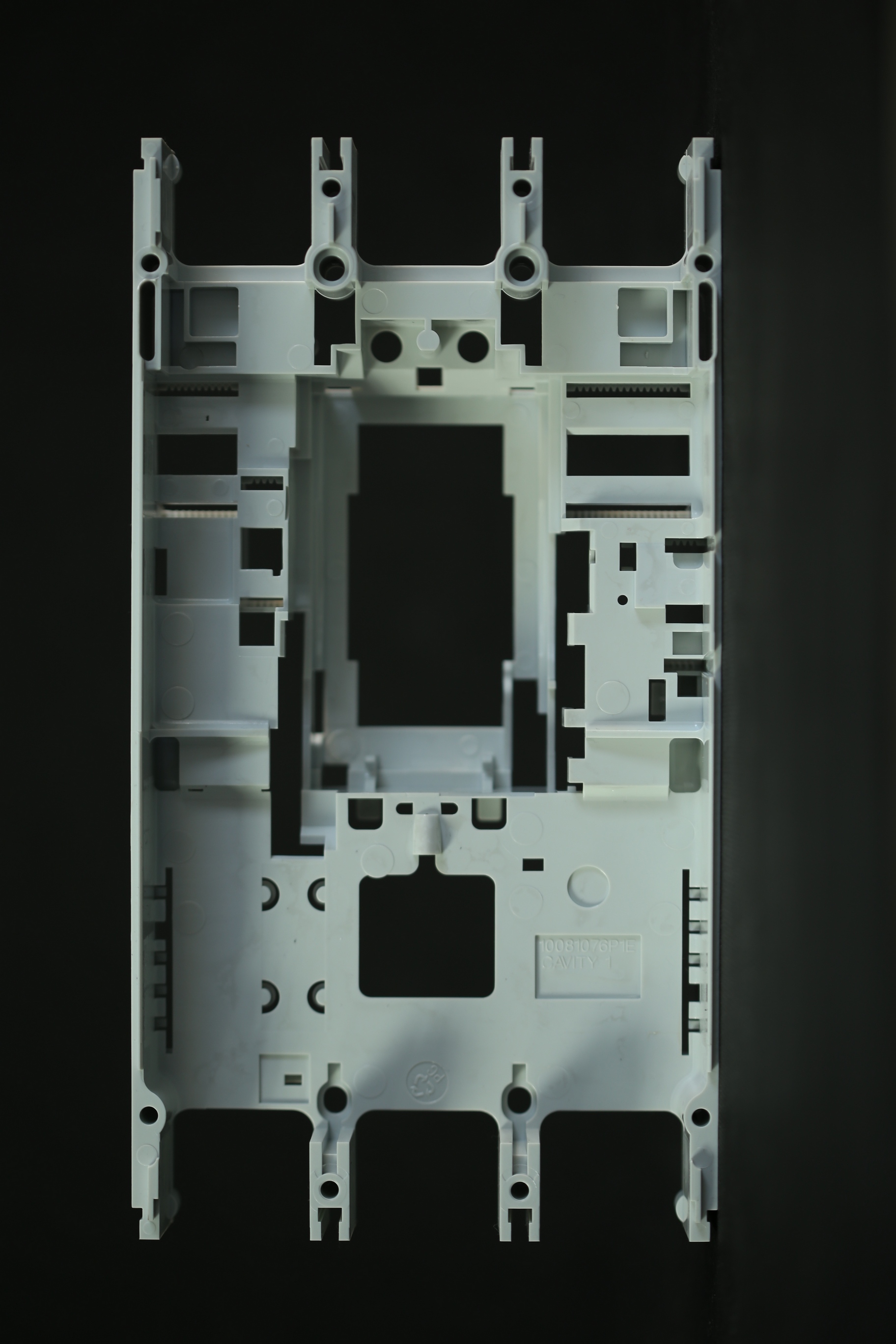

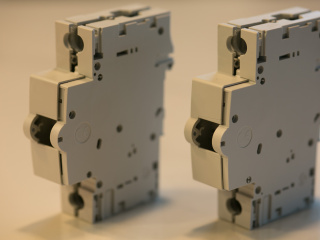

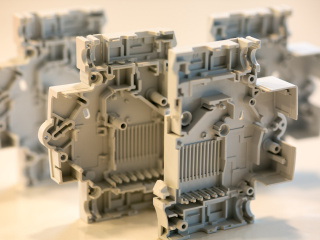

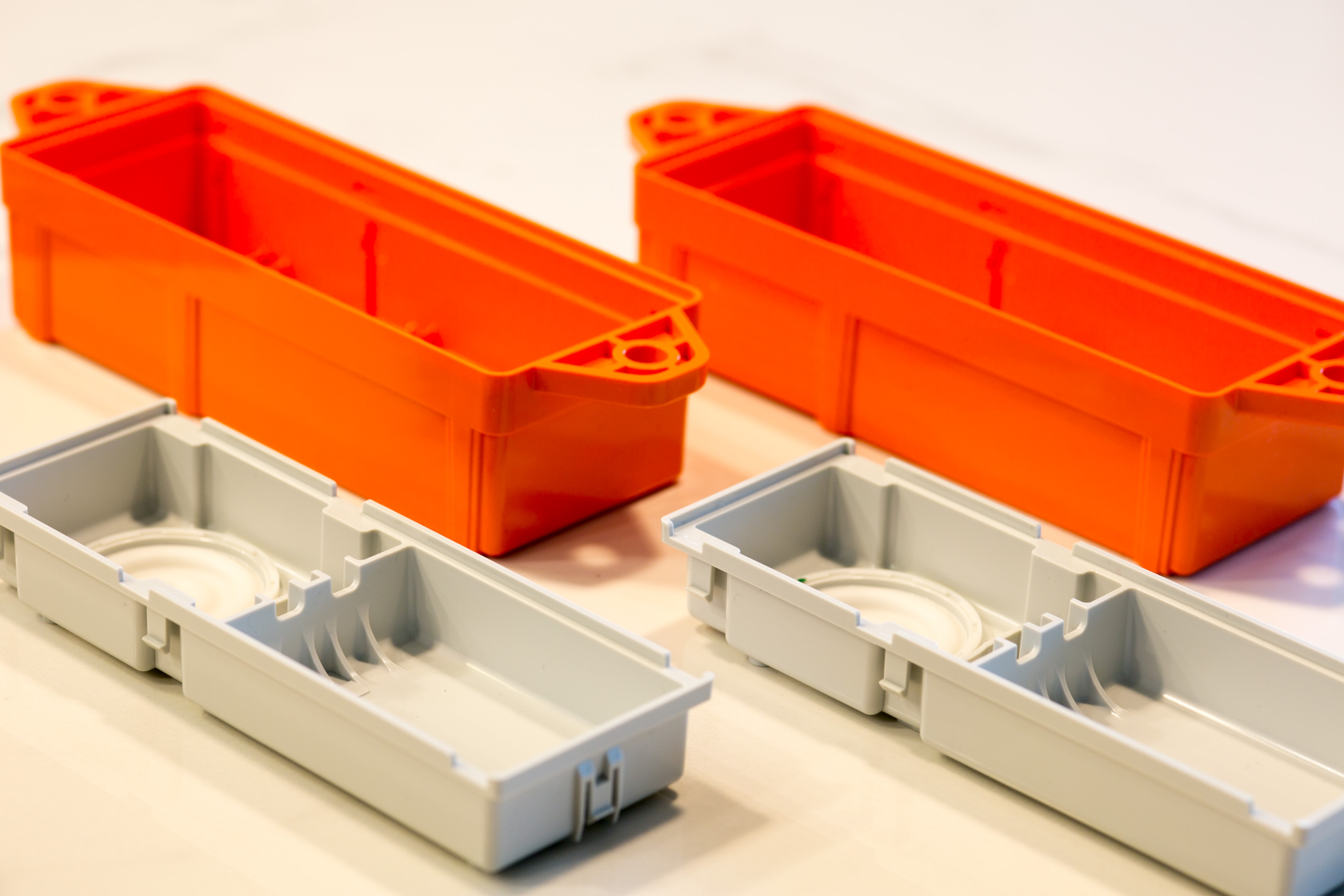

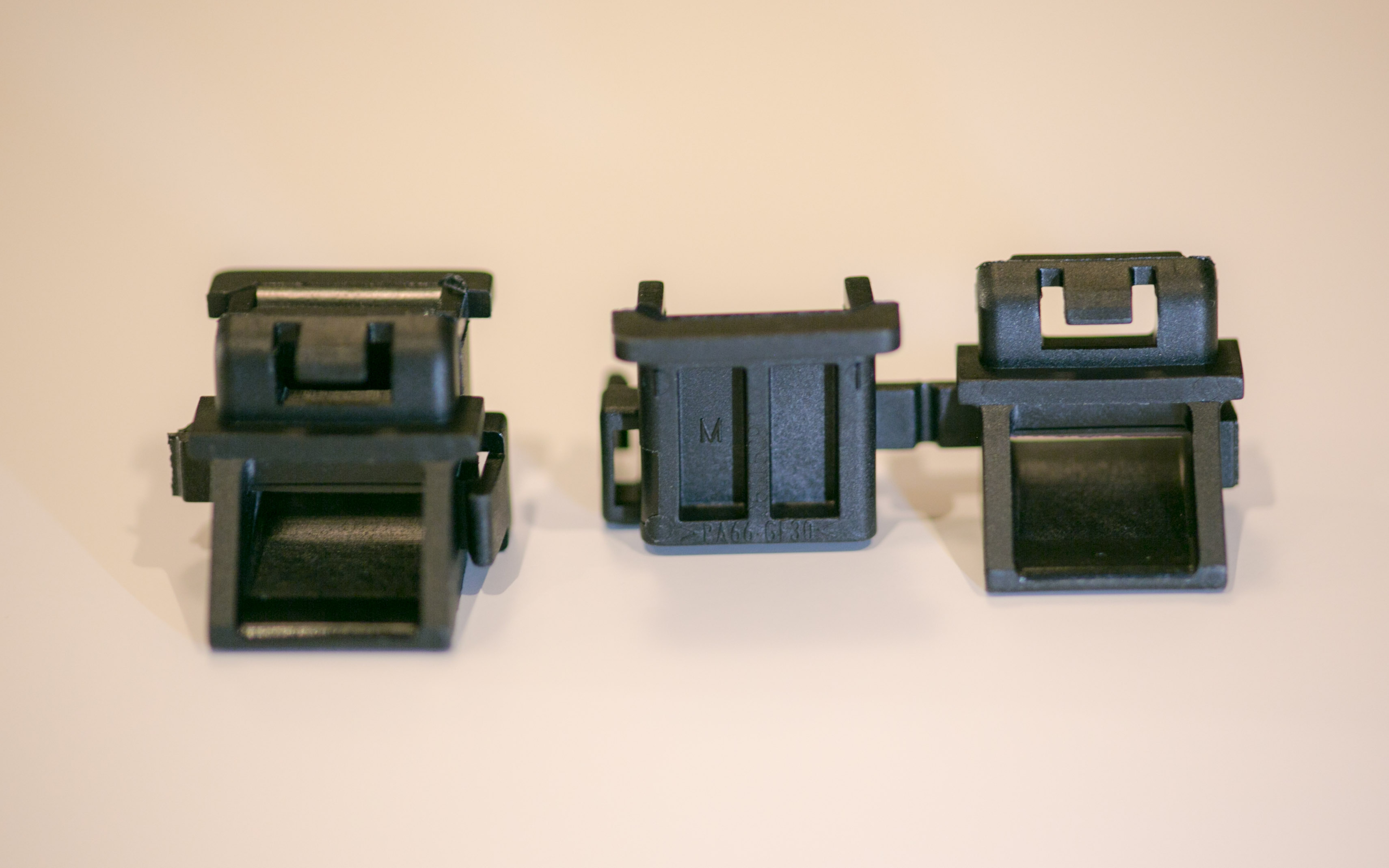

Electroengineering

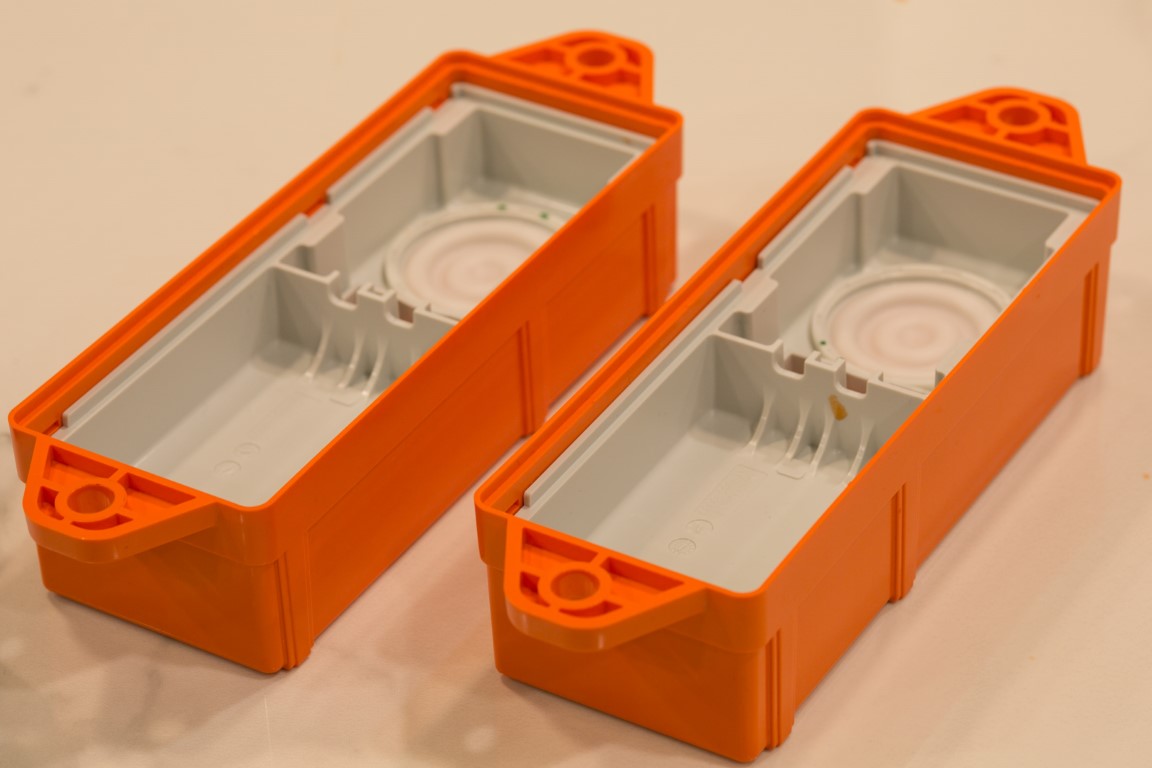

In 2001 we have started cooperation with electro engineering company, producing shafts for electro drills. Over the years this sector has developed dynamically and currently in our portfolio we have more about 700 plastic parts. There are mainly housings for RCD and RCCB, technical parts for automation and control, components for low and high voltage apparatus.

-

Home appliance

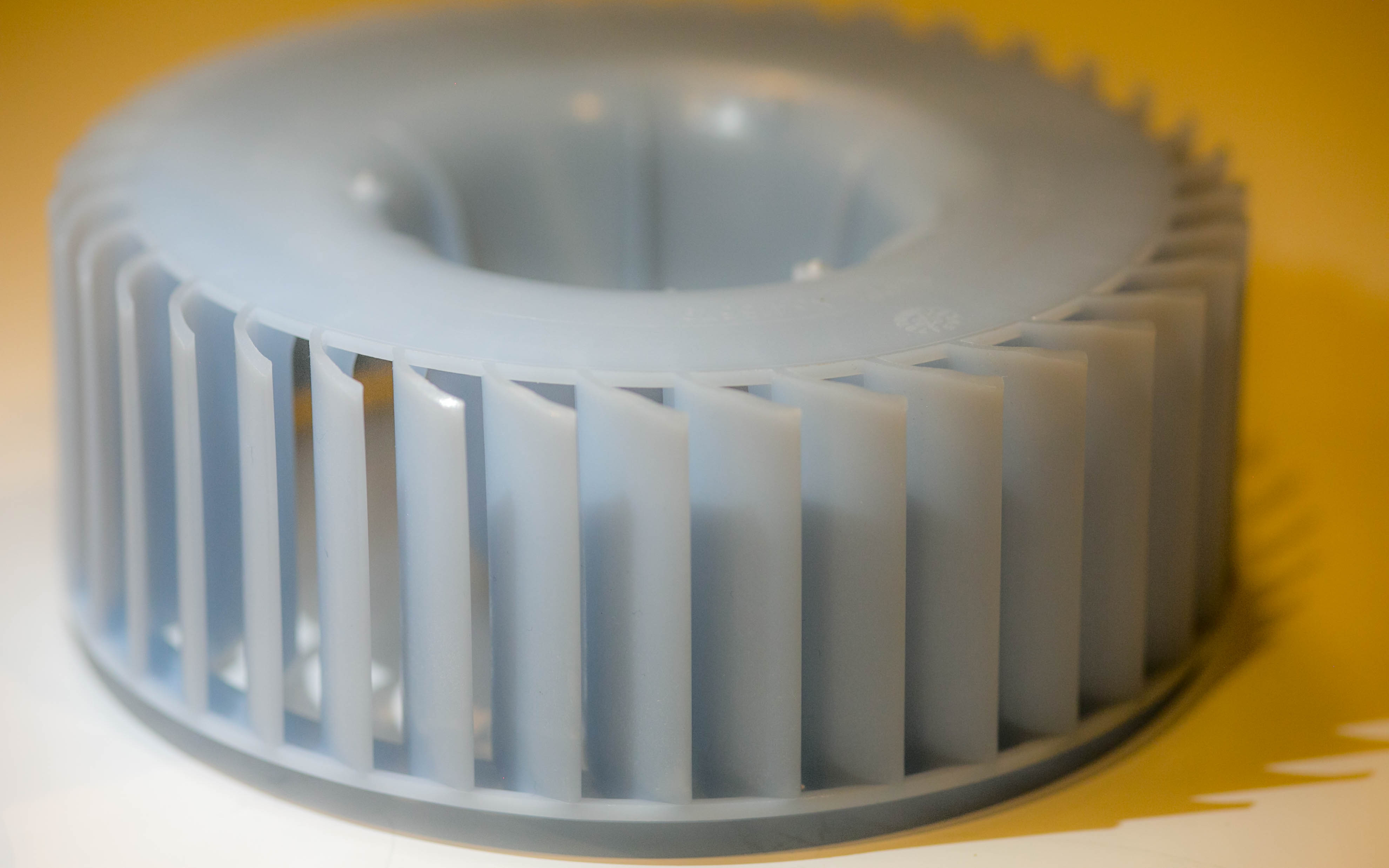

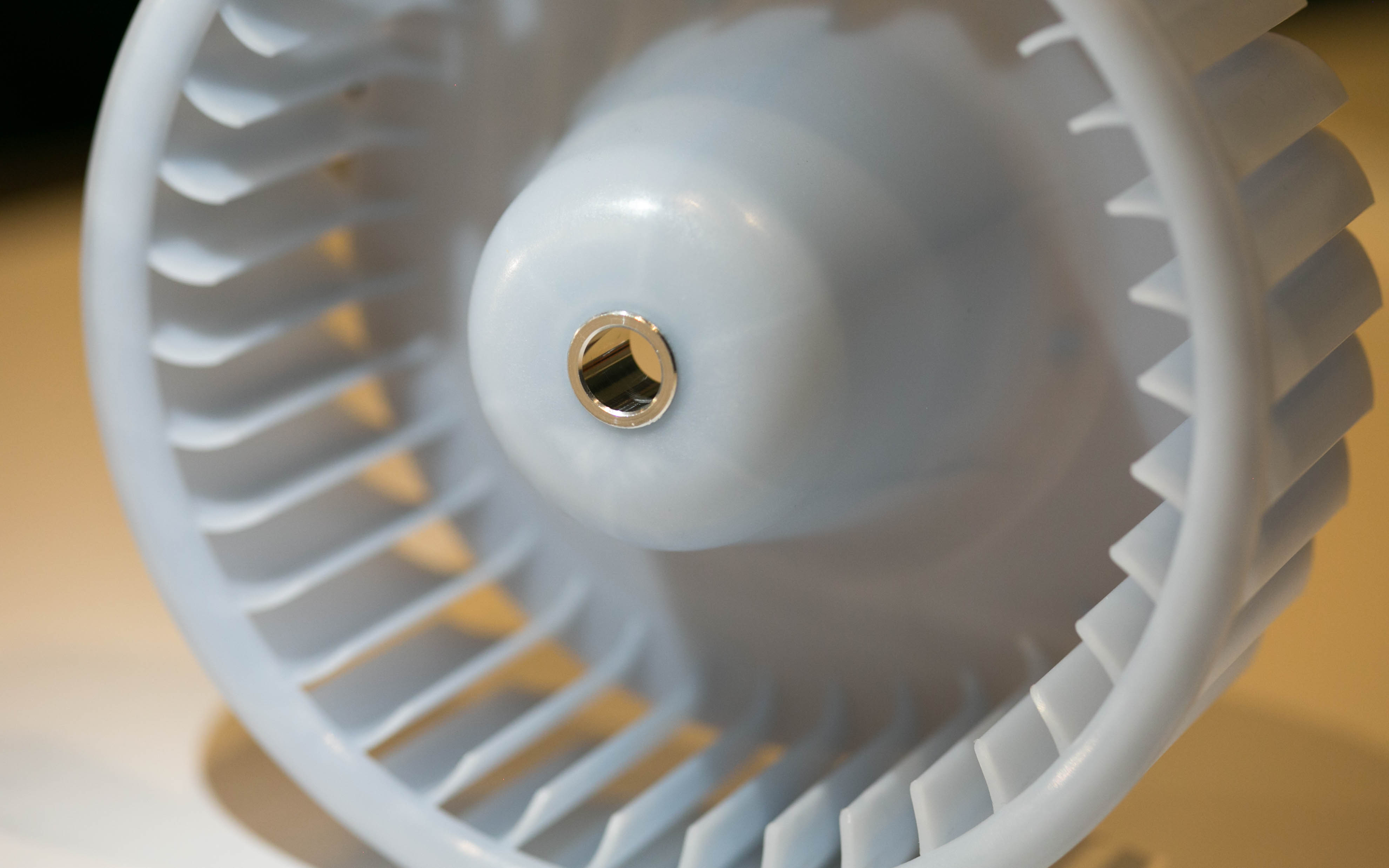

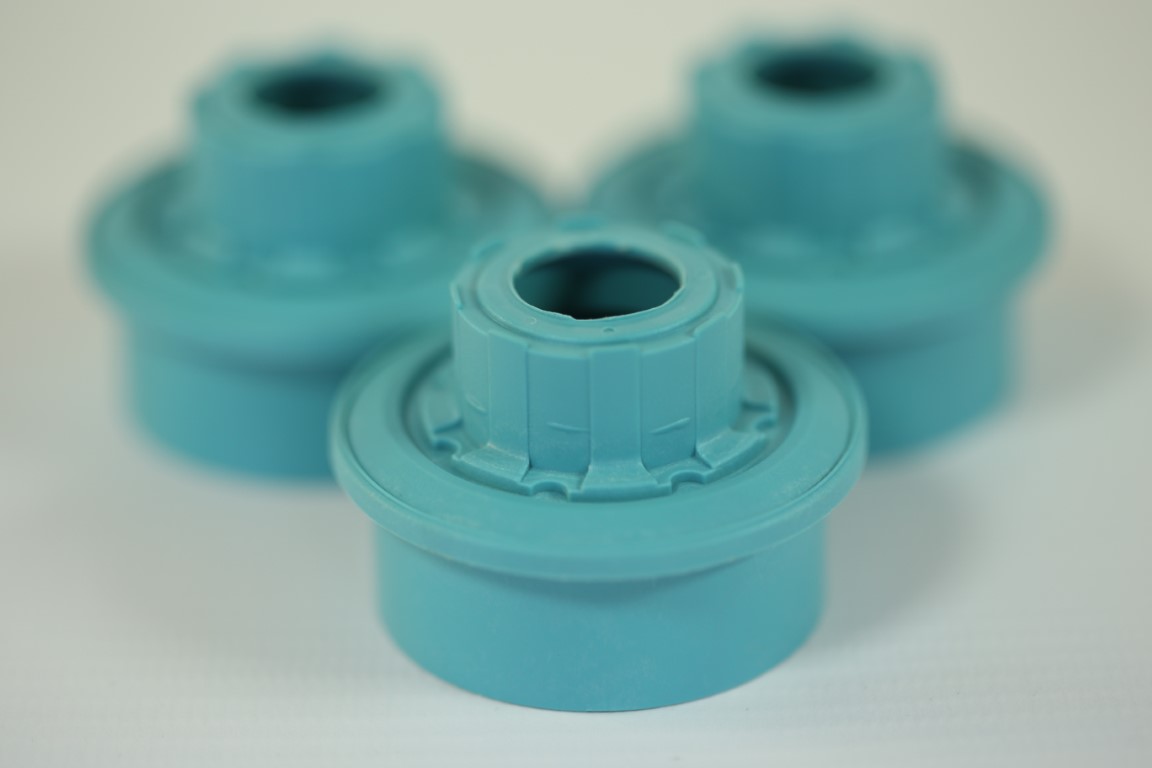

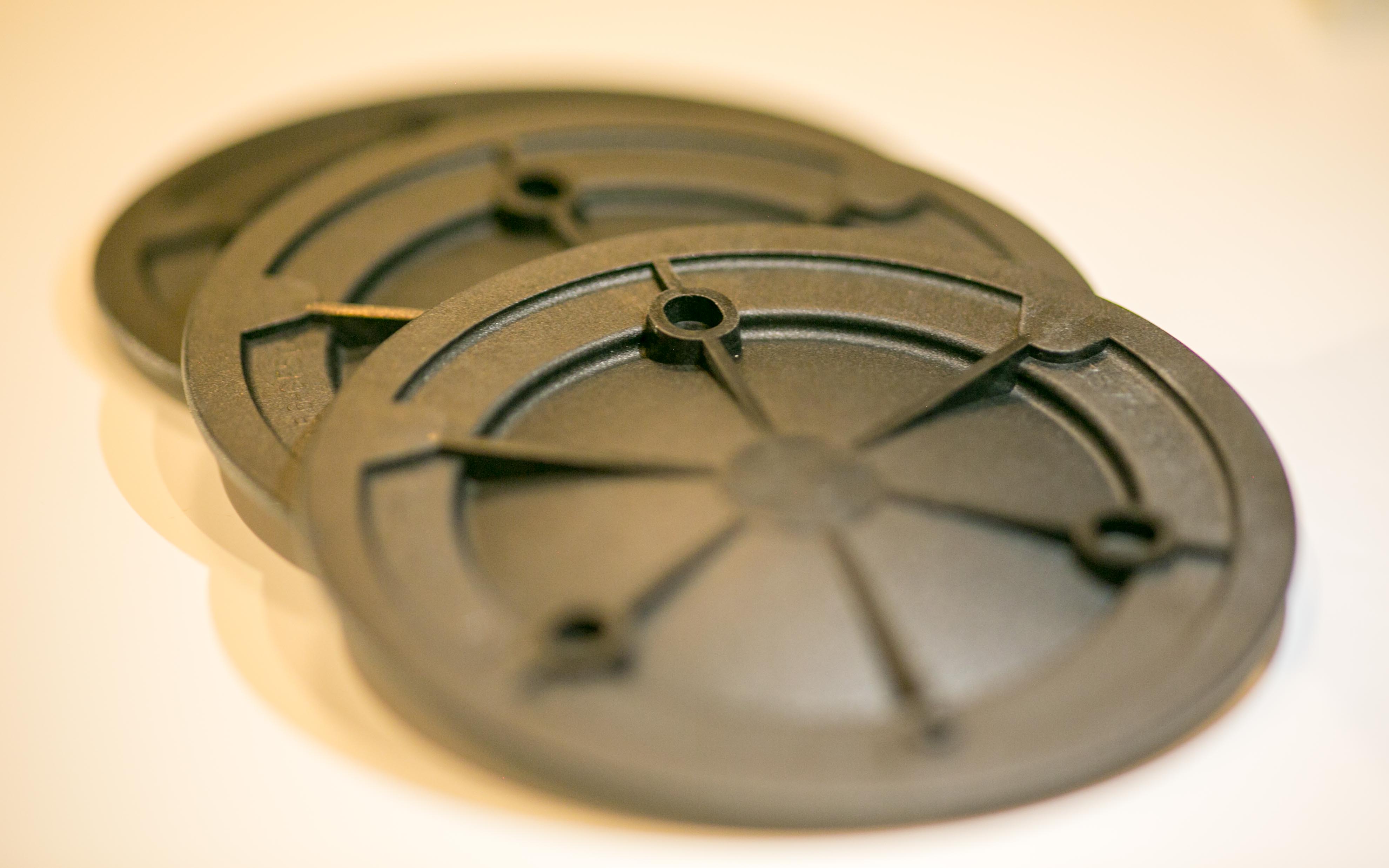

In 2010 we have started cooperation with BEST Poland (ELECTROLUX). Over the years, we have gained the knowledge and experience in production of plastic cylindrical parts which require balancing. They are manufactured in overmolding technology with inserts. Currently, we produce more than 60 components for washing machine, washing and drying machines, dish washers including 2K parts, visual and also chromed plastic parts.

-

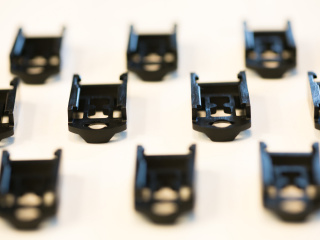

Interior Decoration

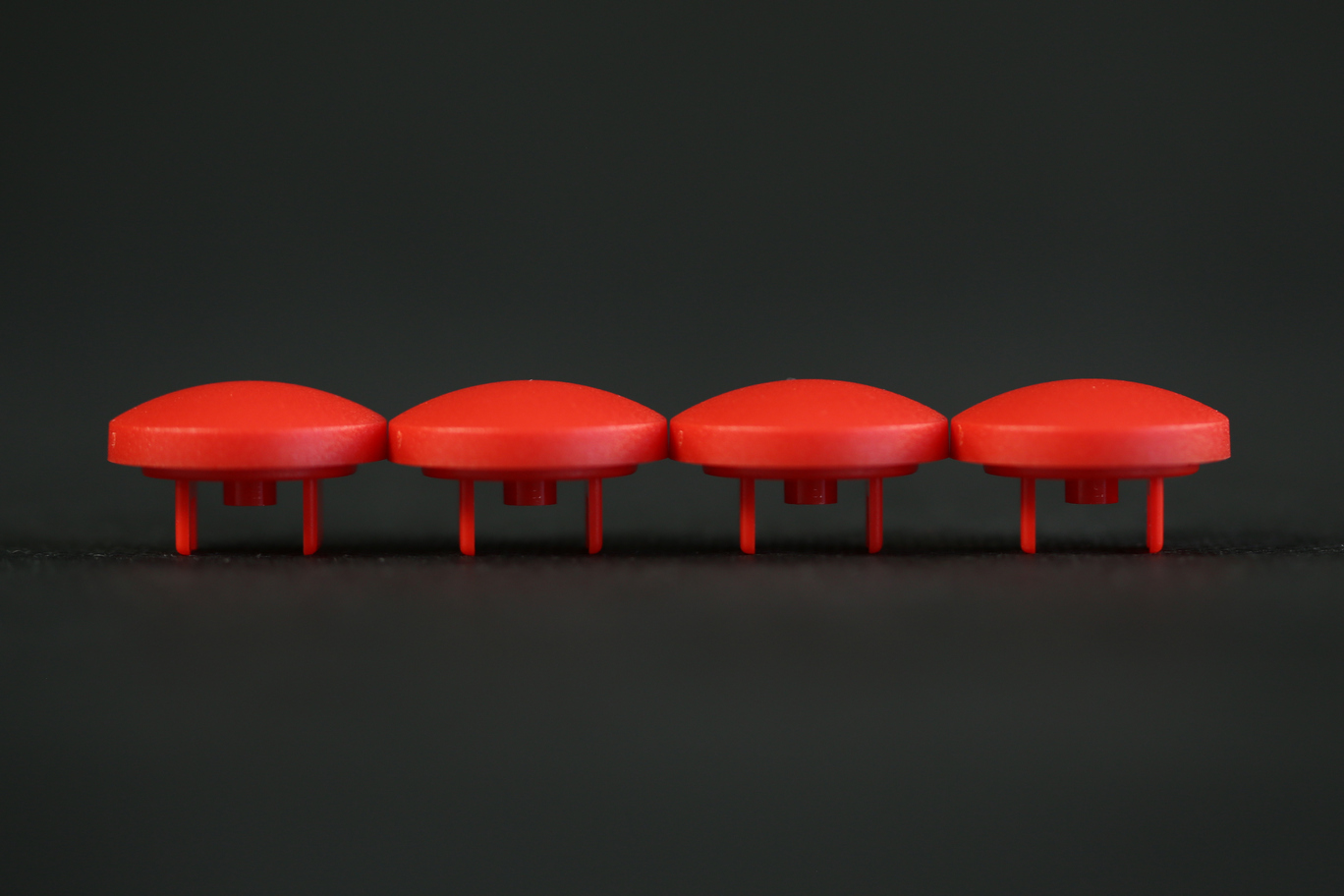

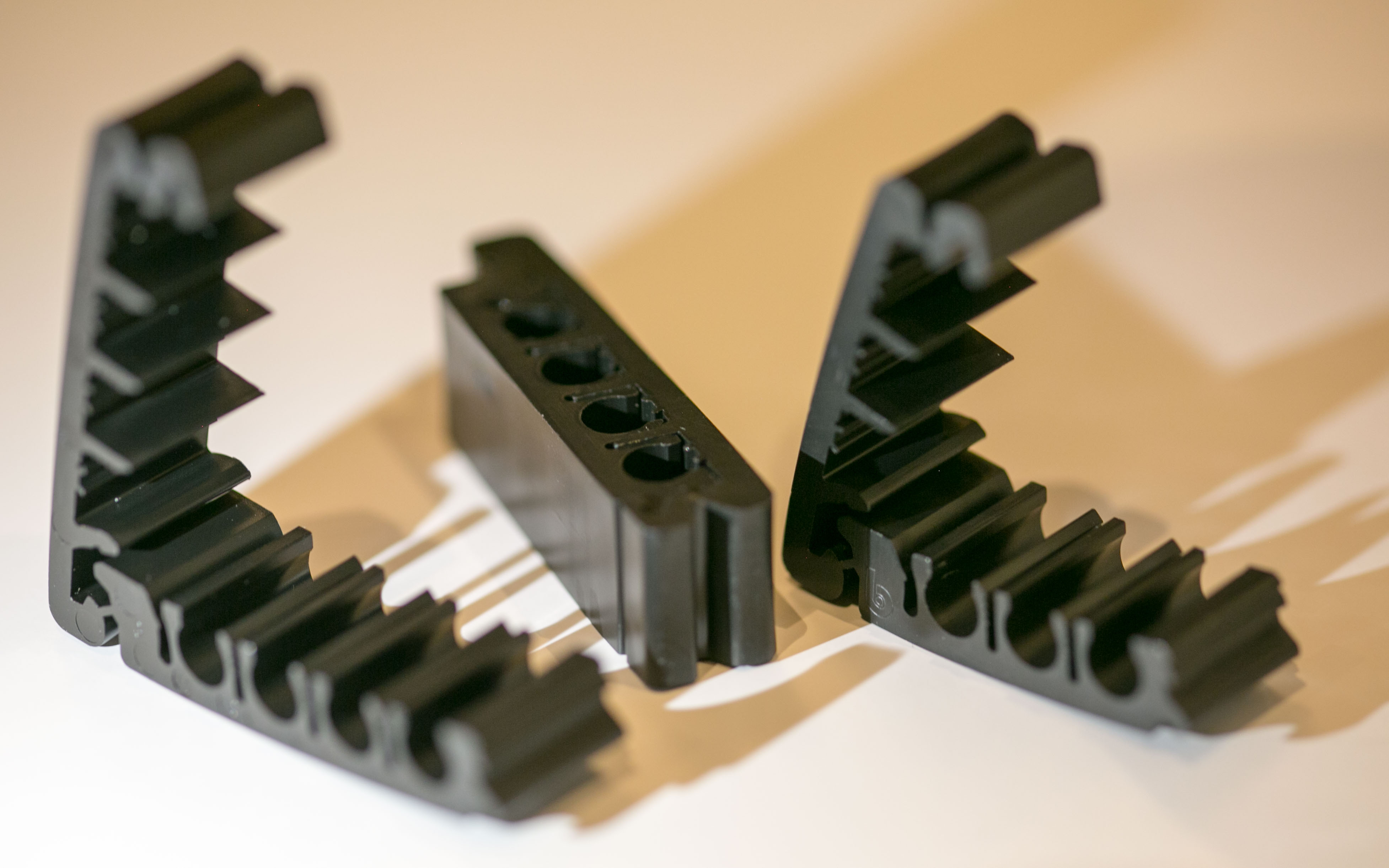

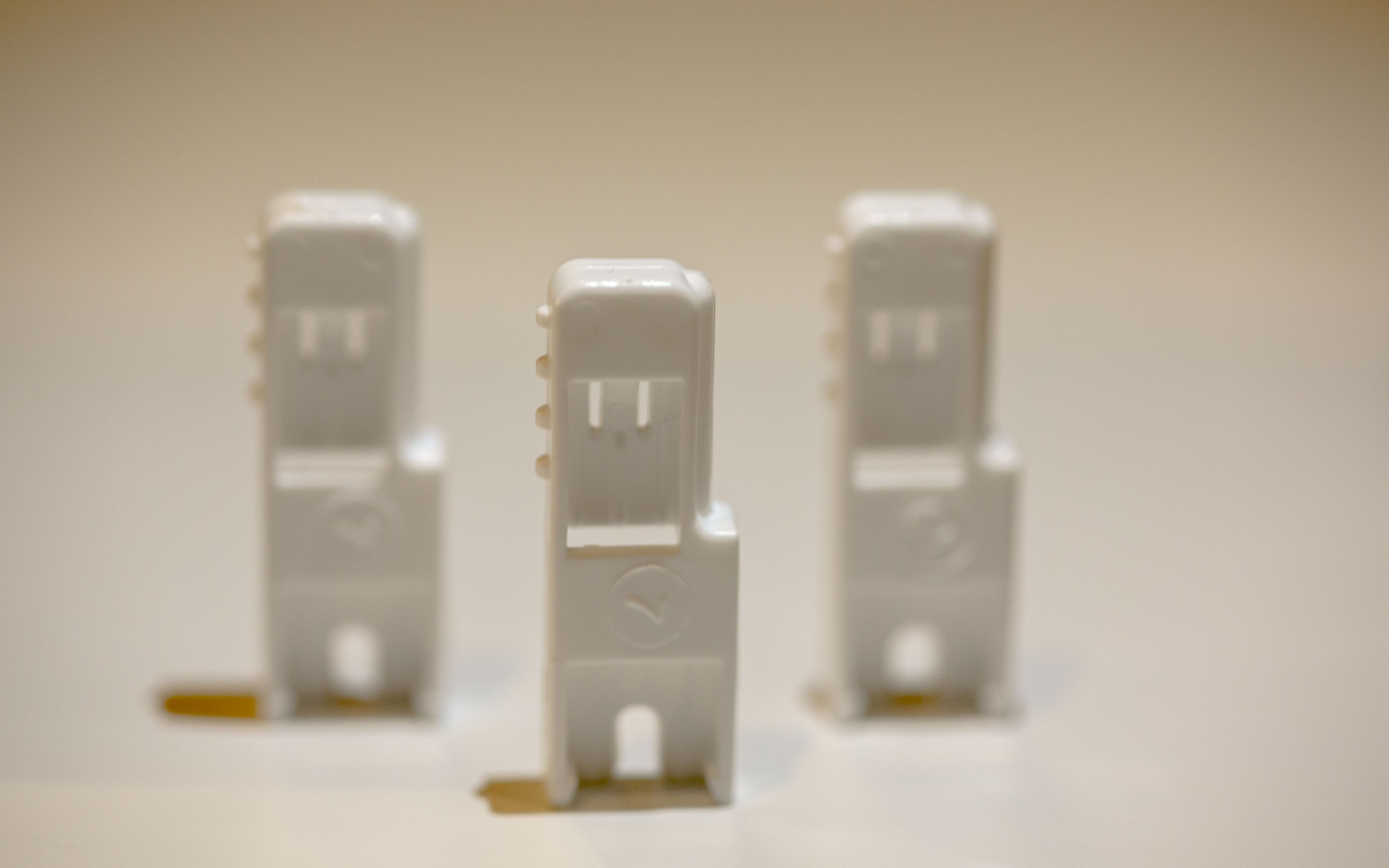

Initial activities of Improdex are dated at 1994 - there were mainly production of some elements and accessories for ceiling rails. Over the years we were developing the products in this sector offering new components also in different colors. Today we produce about 90 interior parts for rail systems such as clips, rings, hooks or rail supports. We pack, identify and deliver those components locally and externally, according to the customers` specifications

-

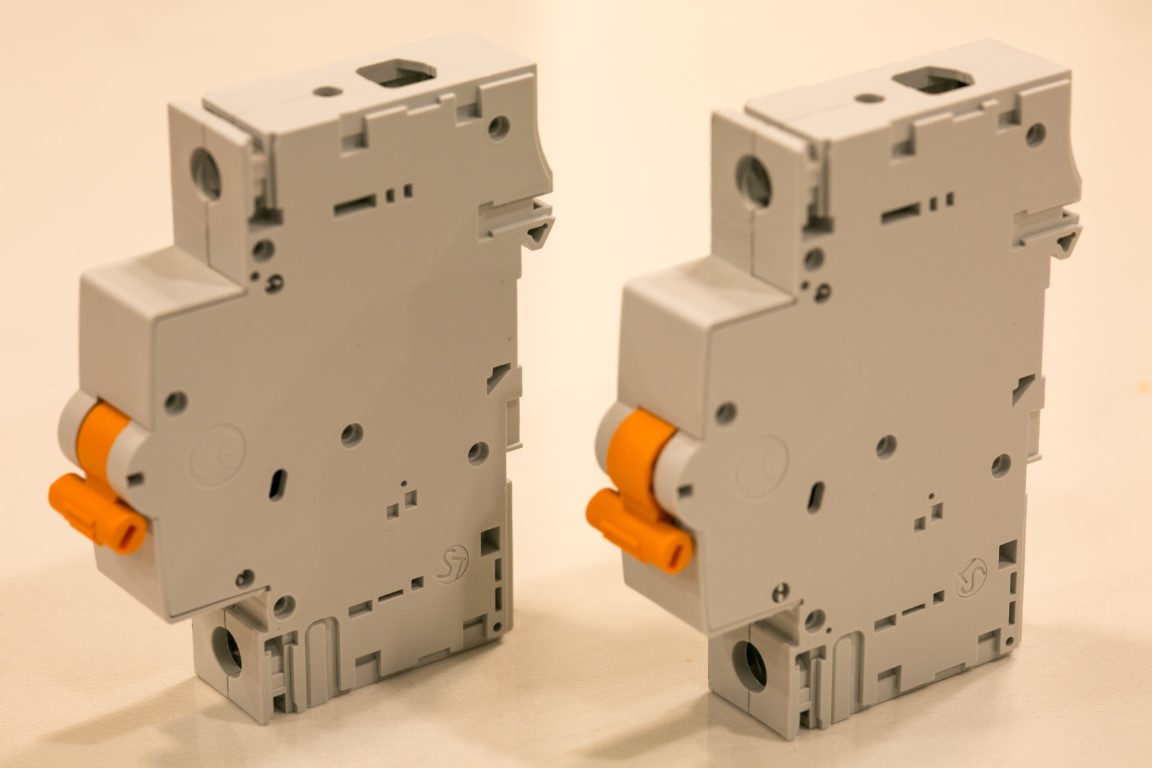

Electroengineering in construction

In December 2020 in order to diversify the products we can offer to our customers, we have launch the electro-engineering components which are installed in construction products - automatic breakers

-

Other industrial sectors

Apart from above mentioned sectors, we also produce plastic components for electronics (EMS), for medical and physiotherapy equipment, hydronic engineering and gardening – developed by Improdex the complex system for gathering the rainwater i.e. linear drainage system.

Portfolio

Look at our projects

Our customers

Who / Since when / Our score

ABB

Kłodzko since 2003

Bielsko-Biała since 2012

No rating

ASK

Bielsko-Biała, since 2007

Audit results 88%

ASTAR

Bielsko-Biała, since 2018

No evaluation

BOJANEK

Częstochowa, since 1998 r.

Very good supplier

Delphi

Jeleśnia, since 2003

Audit results 100%

BOS

Tychy, since 2005

Audit results A

BSH

Łódź, since 2015 r.,Głogów M., since 2020 r.,Chuzhou, since 2020 r.

Supplier rating: A/99%

BWI Group

Krosno, since 2006

Audit results A/99%

CEBI Poland

Sosnowiec, since 2013

Supplier rating:96%

CONTEYOR

Czechowice-Dziedzice, since 2019

Supplier rating: 100%

Cooper Standard

Bielsko-Biała, since 2007

Excellent supplier

ELECTROLUX

Dąbrowa G., since 2010 r.

Supplier rating:A/99%

GARDINIA

Domasław, since 1998 r.

Very good supplier

HL-Display

Dąbrowa G., since 2023 r.

Hutchinson

Żywiec, since 2005

Supplier rating 96%

HAGER

Tychy, since 2021

Supplier rating:90%

IMI

Olewin, since 2019

Supplier rating: 86%

WAWRZASZEK

Bielsko-Biała, since 2005

No rating

Johnson Electric

Dąbrowa G., since 2009

Preferred supplier:A/97%

Kwangjin

Tychy, since 11.2022

Preferred supplier:A/90%

MAGNA CTS

Tychy, since 2011

No rating

Namyang Nexmo

Będzin, since 9.2024

Audit results:92%

Nexteer

Tychy, since 2009

Audit results 91%

PRO-CARS

Tychy, since 2002

No rating

Rockwell Automation

Katowice, since 2010

Supplier rating:98%

TI Fluid Systems

Bielsko-Biała, since 12.2024

Audit results 95%

Trelleborg

Czechowice Dz. od 2005

Bieslko-Biała - 2020

Supplier rating: 100

Tristone

Wałbrzych, since 2002

Supplier rating: 2

SIGIT POLAND

Skoczów, since 2011

Supplier rating: 100%

POLAND

SHILOH

Bielsko-Biała, since 2017

Supplier rating: 100%

POLAND

Asteelflash/USI

Bad HersfeldUstroń, since 2022 r.

Audit results:92%