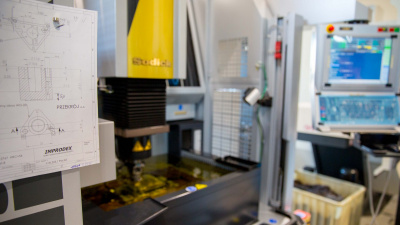

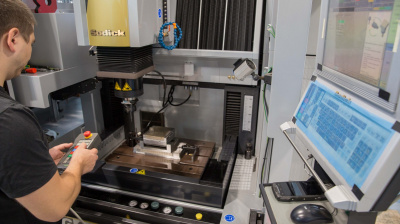

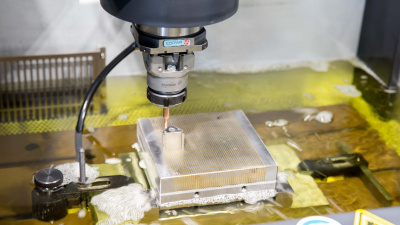

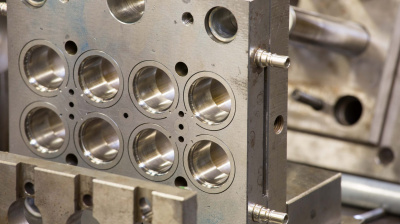

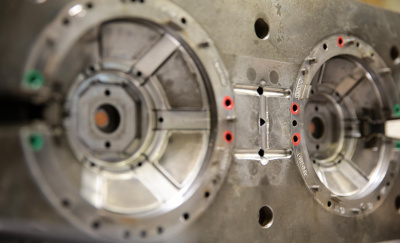

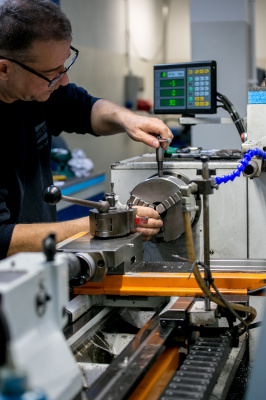

The tool shop is an essential part of a modern injection molding plant. A diversified machines and experienced staff guarantee quick, effective and comprehensive repairs of injection molds. This allows us to shorten production downtime.

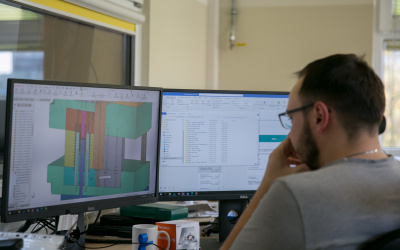

We have a great number of machines from renowned manufacturers - DMG, CHMER milling machines, SODICK boring machines, which, together with many years of experience in servicing injection molds, makes our tool shop a completely independent department, equipped with all the necessary machines, devices not to mention qualified employees.

Thanks to our construction and technological background, we can produce new molds for our clients such as: ABB, Rockwell Automation, ASK, Johnson Electric and others. We have the necessary knowledge and experience to meet the most demanding projects. In our tools we use a considerable number of standards, such as: MEUSBURGER, KNARR, HASCO, STRACK, which guarantee the high quality and reliability.