THE ROLE OF QUALITY CONTROL IN PRODUCTION

Quality analysis of the products are carried out in our internal laboratory. Every day on each shift we have several quality specialists available. They are responsible not only for measeurements but the whole range of analysis and processes. Below there is short description of the carried out quality activities in our lab:

- LAUNCHING THE PRODUCTION – start-up and approval of each serial production is followed by launching “first good sample”, then “shift sample” and finally “last good sample” which is kept till the next production order.

- USE OF GAUGES – for quick verification of the good quality of the produced components we use different types of gauges. They are made in our tool shop or handed out by our customers

- SPC ANALYSIS – is carried out using SPC for EXCEL by applying periodic reports or X-R charts, where statistics data are examined

- MSA ANALYSIS – are carried out for numerical and attribute measurements using ANOVA or KAPPA methodology

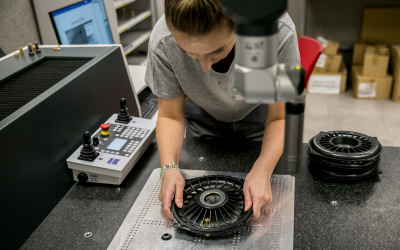

- 3D MACHINES – we use two integrated ZEISS CONTURA 7.10.6 machines with 700x1000x600 mm range for precise contact-type measurements

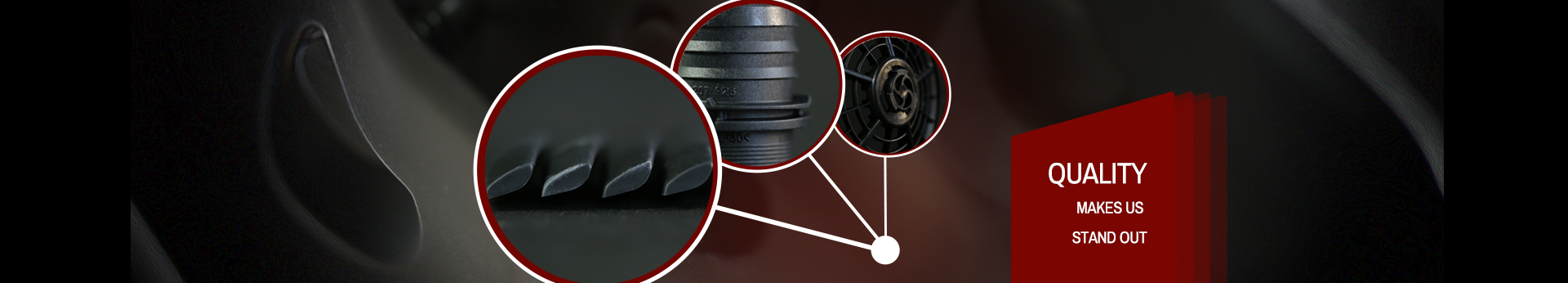

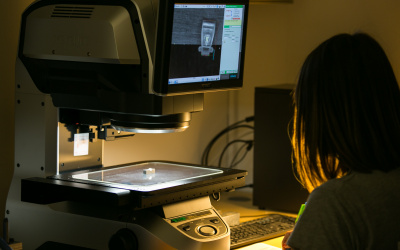

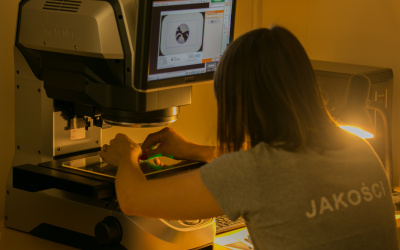

- OPTICAL MACHNIES – two optical fast and precise Keyence machines IM-7500 with 200x100 mm range and IM-8030 with 200x300 mm and additional Mitutoyo PJ-A3000 shadow graph with 200x100 mm / 0 – 360°.

- CALIBRATION - calipers and micrometers are calibrated internally according to ISO 17025 standard and instructions as well as in external accredited laboratories

- MATERIAL HUMIDITY – is measured each time during start-up of a new process on Mettler Toledo HC103/01 moisture analyzer

- COMPONENTS COLOR ANALYSIS– are measured according to L-a-b on SpectraMagic software using Konica Minolta spectrophotometer

- SURFACE ROUGHNESS is measured on Mitutoyo surface analyzer

- MFR TEST – for some granules we test material flow index using MFI-1221 analyzer according to ISO1133 and ASTMD1238 standards

- PRODUCT AUDITS are done according to VDA 6.5 standard

- PROCESS AUDITS are done according to VDA 6.3 and AIAG standards

- LAYERED AUDITS are done on a daily basis according to internal schedule

- IATF AUDITS are carried out annually according to IATF 16949 and ISO 9001 standards by external accredited body

- CUSTOMER AUDITS are carried out regularly by our customers, on average there are several audits each year, mainly according to VDA standard