Purchase of the plot near Improdex plant to build internal PV installation.Start-up of the assembly line dedicated for components produced in-house by Improdex for our customer in electrotechnical sector.

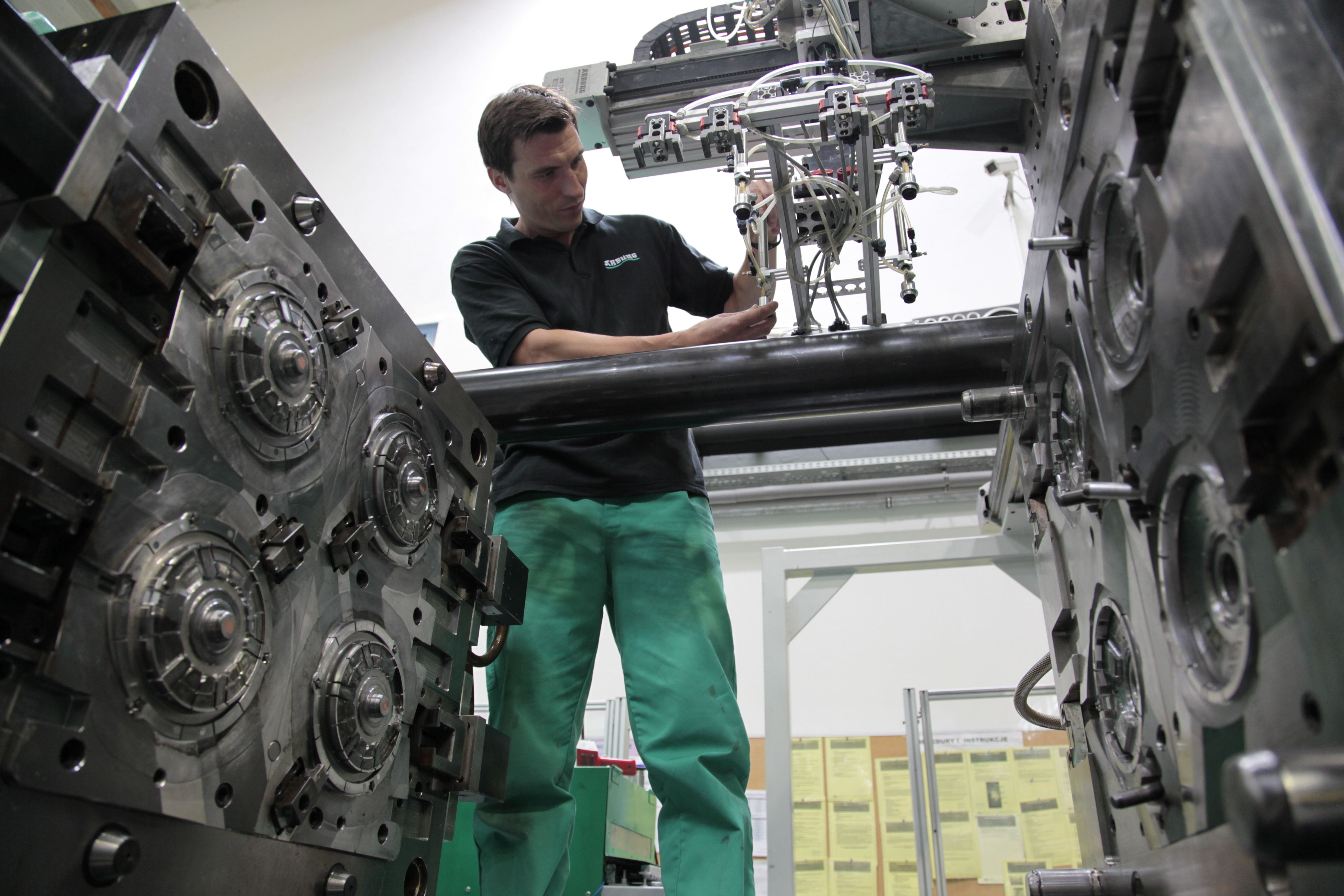

Purchase of the second tampo printing machine, start-up of the circumferential printing process. Installation of the modern ONI fan-based cooling units. Purchase and installation of the biggest in our history ARBURG 920 hybrid machine equipped with MuCell technology. Cooperation with Hager Group in electrotechnical sector.

Development of cooperation with ABB (previously GE) in electrotechnical branch. Utilization of coronavirus anty-crisis government financial grants and nomination of Improdex to EU funded projects. Purchase of several new Arburg machines and completion of new production space at new hall mezzanine, start of tampon printing processes.

The company has 160 employee and produces on 54 presses.

In August Stefan Kazimierz Bułka passed away. A great charismatic man with passion, vision and ideas, who built the IMPRODEX company in difficult times, thus realizing one of his greatest dreams.

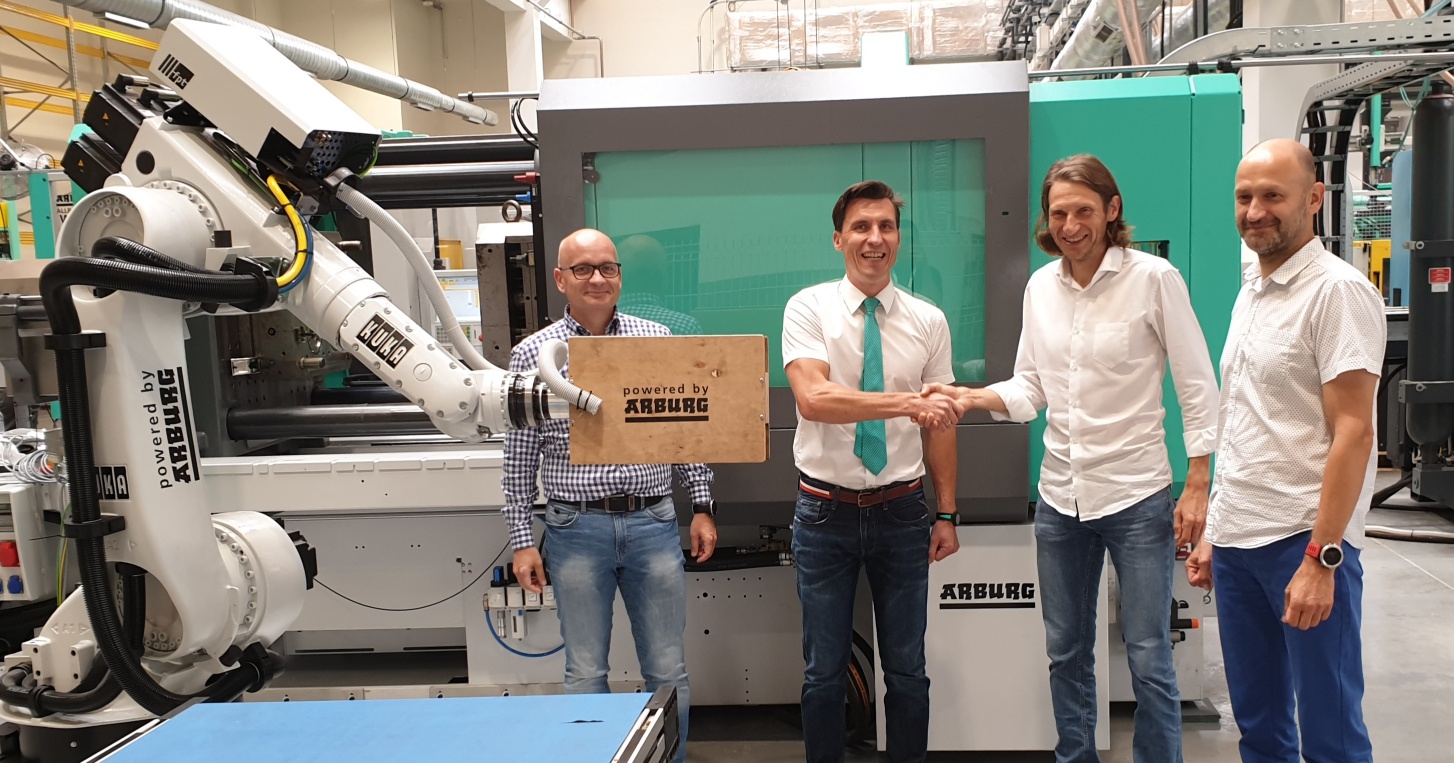

Start-up of cooperation with IMI Hydronic Engineering. Two new innovative ARBURG presses with KUKA robots on the new large production hall.

The 4th award for Improdex for exceptional quality performance among Nexteer`s supplier community. Construction of new hall and implementation of the new Microsoft Dynamic NAV and Arburg ALS software to supervise injection machines.

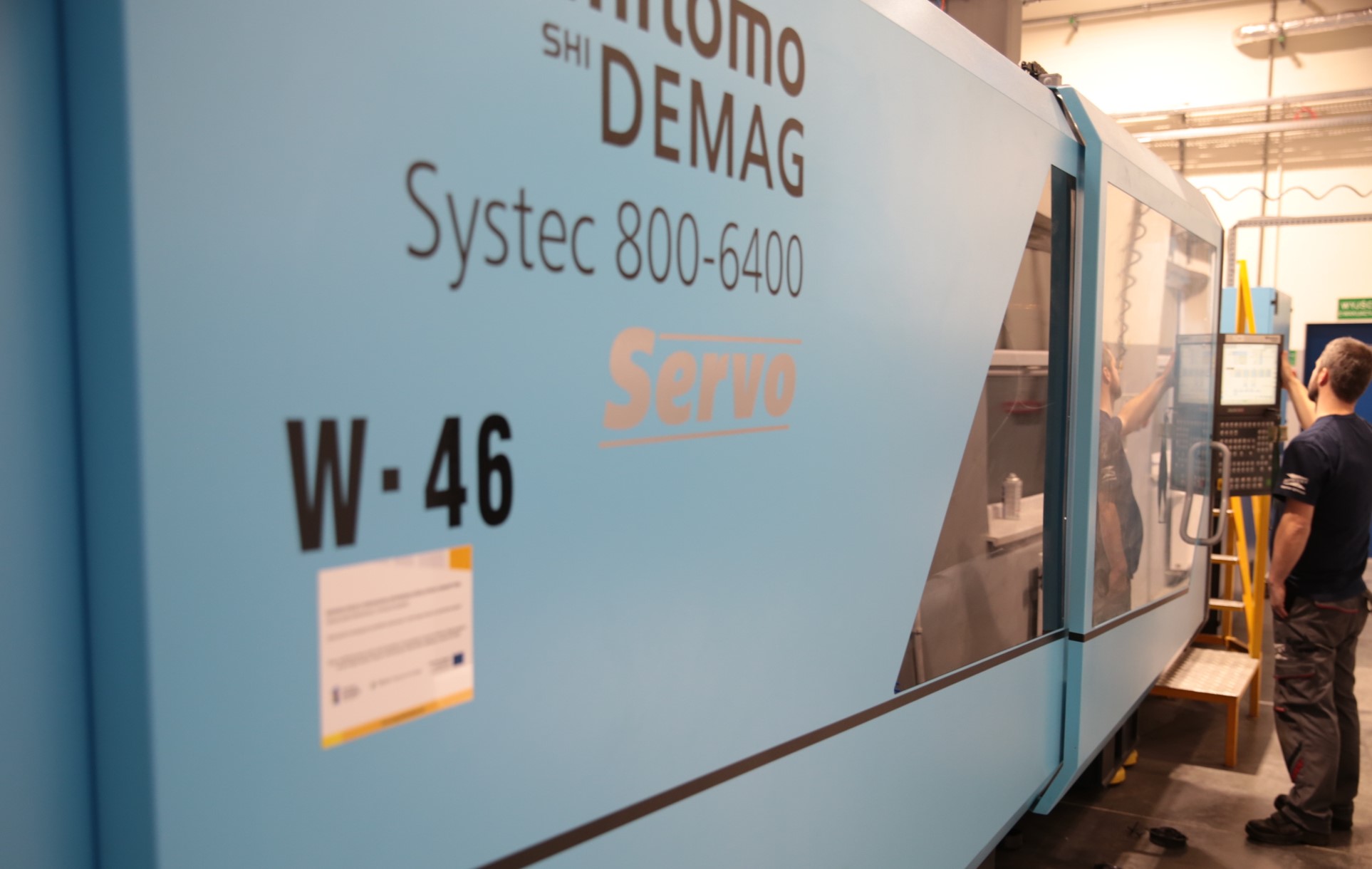

Start cooperation with new companies – ifm ecolink based in Opole and Shiloh Bielsko-Biała. Launch of microcellular gas injection process – MuCell® on 900 tons Sumitomo-Demag machine.

Completion of the III stage of the company extension – the new tool shop, assembly and visual control room with social rooms.

The third consecutive award for Improdex in Automotive sector for setting the standard of exceptional quality performance among Nexteer`s supplier community.

Outstanding Supplier Award from General Electric Energy Management and the second quality award from Nexteer Automotive for 0 complaints and 0 ppm in 2014. Improdex changes its legal form to a limited partnership.

The first important award in the history of Improdex in Automotive sector for setting the standard of exceptional quality performance among Nexteer`s supplier community.

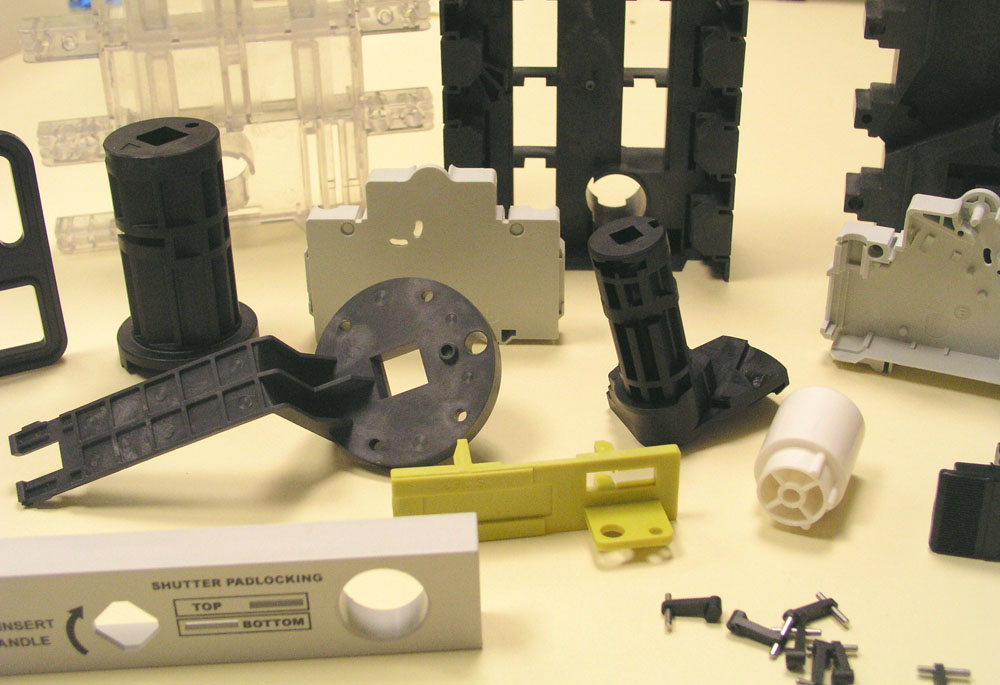

Purchase of a new generation electric-type Arburg machine together with Multilift robot. This is the 30th ARBURG injection machine made for Improdex. Current employment is more than 100 people with production exceeding 1000 plastic components.

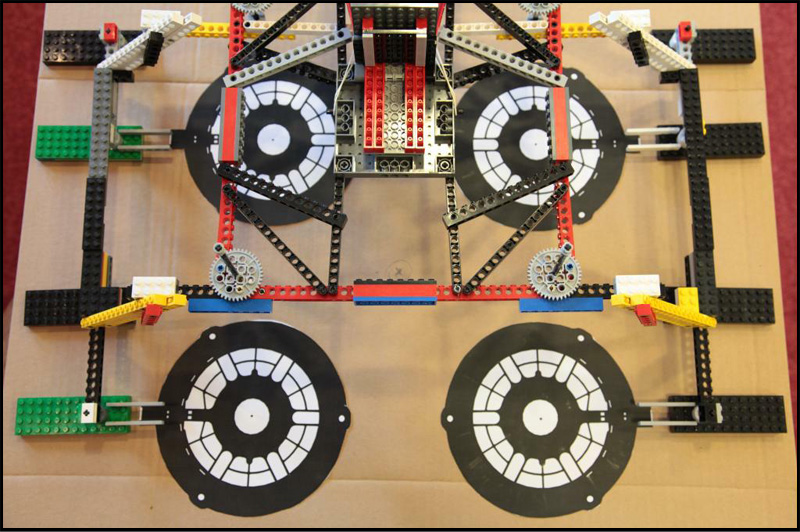

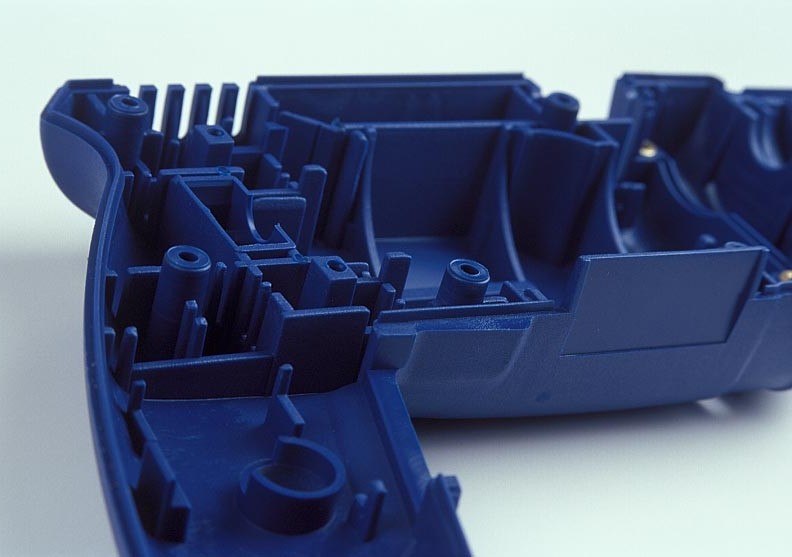

Together with our Client, design and implementation of fully automatized line for production of car audio system baskets together with terminals and metal parts overmolding process.

Completion of the construction works and putting into service a high storage warehouse , which is built as a self-loading structure. Purchase of the biggest machine in history -ARBURG 920 - with clamping force up to 550 tons. Start up production for home appliance sector.

Completion of the construction works for the new production floor with the area of 600 sq m dedicated for small and medium-size machines.

The company has purchased several old machines - lathes, machine tools and grinders to improve ongoing mold repairs. Serial production of speaker baskets for ASK and steering column components for Nexteer Automotive.

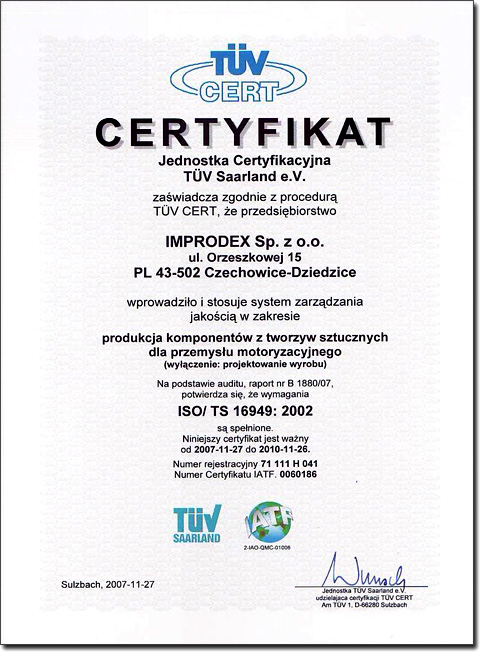

The company implements ISO TS standard, owns 14 machines, 72 employees and produces nearly 400 components for the automotive, electro-technical and interior decoration sectors.

Completion of the biggest investment in the company history. Improdex changes its location, moving to its own new facility. It has a total area of 1700 sq m and includes production floor, high storage warehouse, tool shop as well as social rooms and the office.

Strat up the construction works of a new seat in Czechowice-Dziedzice on a piece of land purchased in 1999.

A concept is created and an architectural design is commissioned for the construction of the company's new headquarters. President of the company - Stefan k. Bulka designs a new product and makes an injection mold for a curtain rod wheel - a frog with a hook, along with an assembly concept.

Implementation of a new IT program for company management CDN-XL by KSI from Bielsko-Biała.

Start up the cooperation with GE producing electro technical plastic parts for high voltage breakers.

For the first time in history of Improdex, purchase of a first new big ARBURG 820S injection machine with 400 tons clamping force, mainly for production of bigger plastic parts - shafts and bodies for electro drills.

After implementation of QS-9000 system, there starts the development for automotive sector, mainly for Hutchinson and Trelleborg.

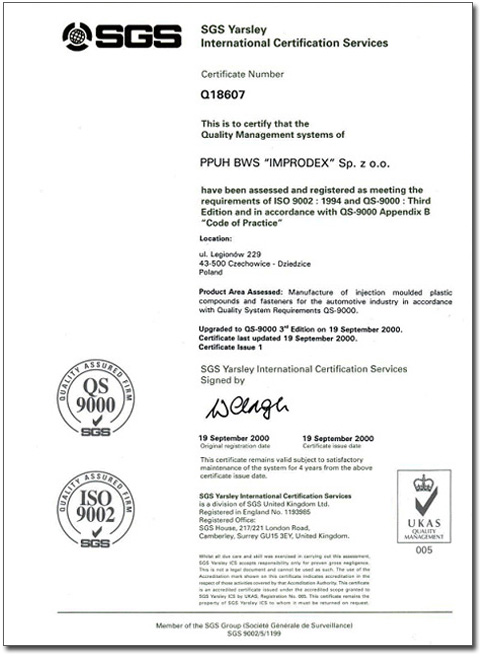

Improdex implements QS-9000 quality system for automotive sector and renew current ISO 9001:1994 to develop production for other sectors. The main customer is still GARDINIA with sales offices located all over the Europe.

Stefan Kazimierz Bułka – the chairman, takes some activities to purchase a piece of land aimed at a long-term company development plan. Finally an area of 1,5 ha is purchased from central heating plant in Czechowice..

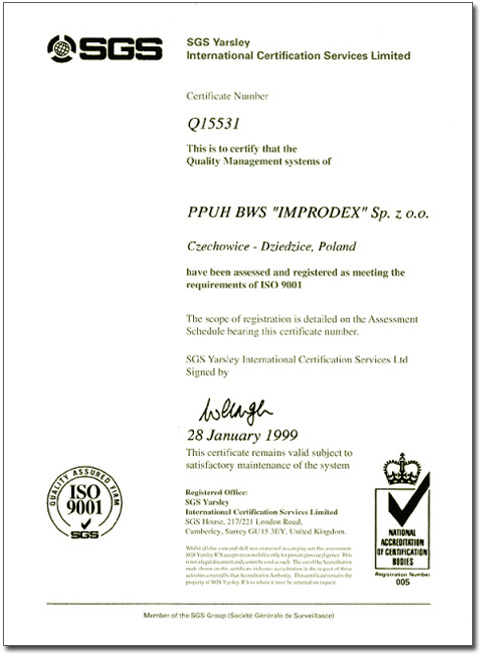

The company implements ISO 9000:1994 quality certification and begins cooperation with Delphi, supplying the first components for the automotive industry.

After a year of work, Improdex has a new renovated plant at 187 Legion Street and employs 25 people.

Due to production constant increase, there is a need to change the location so as to further develop the company. Decision is taken to rent some old production rooms PSS Społem and carry out its refurbishment to accommodate for production hall.

Improdex owns 5 injection machines and produces mainly accessories for curtain and ceiling rails such as clips, hooks, rings and supports.

The new shareholders become the member of the family. After the purchase of the first KuASY injection machine in the garage in the private house, a production of some simple accessories for curtain rails is started.

Stefan Bułka Senior in his private house in Czechowice-Dziedzice set up a company named BWS Improdex, which deals with different activities within trade, production and other services.

.jpg)