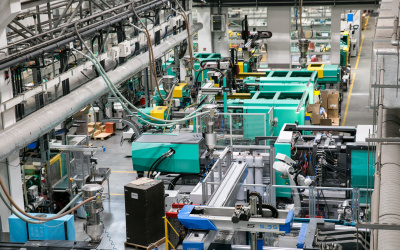

Since 1998, we have been producing on ARBURG machines - German company - a leading manufacturer of injection molding machines. Currently, we have 58 modern machines with clamping forces ranging from 25 to 800 tons, with the possibility of injecting components with a volume of up to 2100 cc, including 3 vertical machines with rotary tables and 3 machines dedicated to two-component production.

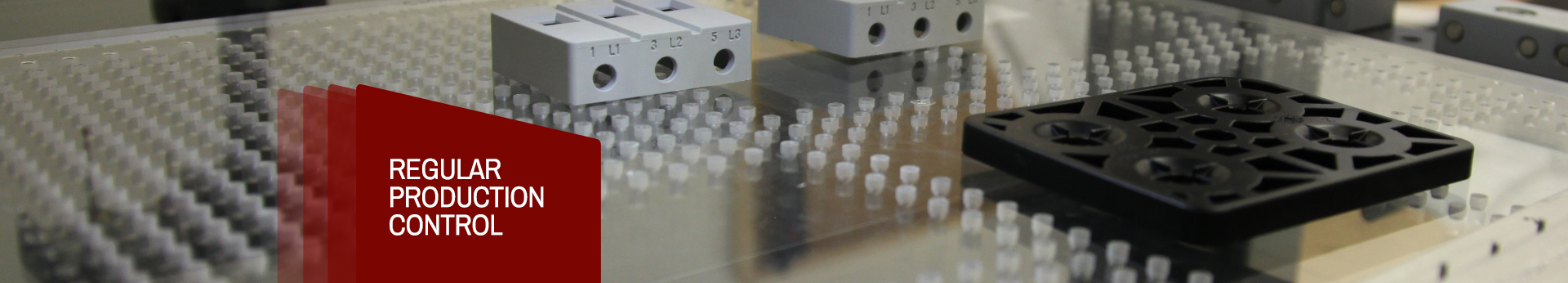

57 machines are Arburg latest generation injection molding machines and 1 machine with a clamping force of 800 tons - Sumitomo-Demag, on which we carry out production with gas foaming in MuCell technology. All machines are equipped with software which optimizes the production process, packages for monitoring the quality of molded parts and also flaps for sorting any nonconforming components.

In 2019, we implemented the ALS system - the so-called a master computer system that enables supervision and control of the entire production and process parameters in every press. Thanks to this, we achieve a high quality of our product and also shorter downtime. At any time, one can view the process parameters of ongoing order in-progress, their changes in time and quality performance with production efficiency parameters (OEE).

Reinforced plasticizing units enable the processing of thermoplastic plastics with a high content of aggressive and corrosive fillers and raw materials with a high plasticization temperature.

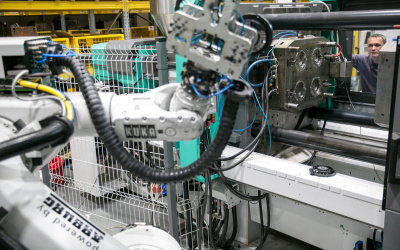

Our machines are equipped, to a large degree, with a number of connections for controlling peripheral devices, such as: robots (3 and 6 axes), hot runner systems, hydraulic and pneumatic cores.

We have extensive equipment that helps optimize production processes and minimize errors; these are: ARBURG, KOCH and PIOVAN automated circulation dryers, dye feeders, conveyors and the ONI central cooling system.

Thanks to a considerable investments into modern machinery and thanks to our qualified staff, we can realize orders for the most demanding customers.