08 may 2019

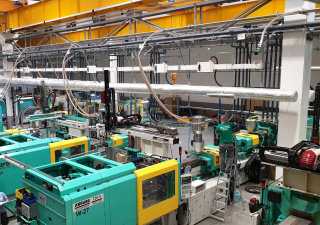

TRANSFER OF BIG MACHINES INTO THE NEW PRODUCTION FLOOR

For the last two months there have been quite intensive works related to the transfer of all the big injection machines (350-800 tons) into our new production facility. Currently all machines are connected to the new ONI system for cooling tools and machine`s oil. Furthermore all the new machines are supplied by new central material feeding system. In addition, new efficient lighting system together with sun roofs as well as ground exchanger ventilation system make the comfortable working conditions. By now, the new facility is covered with the machines already up to 60%.

14 november 2018

NEW FACILITY FOR BIG PRESSES

The vast majority of construction works of the new facility have been completed. In October, we have finalised the installation of two 16 tons crane beams, we have completed illumination, ventilation, electricity, rain and wastewater systems as well as fire protection installation. In November, an industrial floor was made, which is currently in the conditioning phase.

.

26 october 2018

4TH AWARD FROM NEXTEER AUTOMOTIVE

For the fourth time in a row, we received a prestigious award from one of our major customer - Nexteer Automotive. Delivering nearly 30 different plastic components, we achieved in 2018 the highest level of customer satisfaction - 0ppm and 100% deliveries on time. Such high quality index have led us to the prize award - for setting the standards of exceptional quality performance among Nexteer`s supplier community. Earlier we received the rewards in 2013, 2014 and 2015.

01 june 2018

NEW FACILITY FOR BIG PRESSES

08 march 2018

PROCESS AUTOMATION

In March, thanks to introduction of automation processes in our production of basket for ASK, we have unified two operations – injection and over-molding processes. Actually, the over-molding process takes place directly after the injection process without the semi-storage phase of baskets. This considerable investment in automation has improved the work flow and may contribute to elimination of the operators in the whole process.